NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

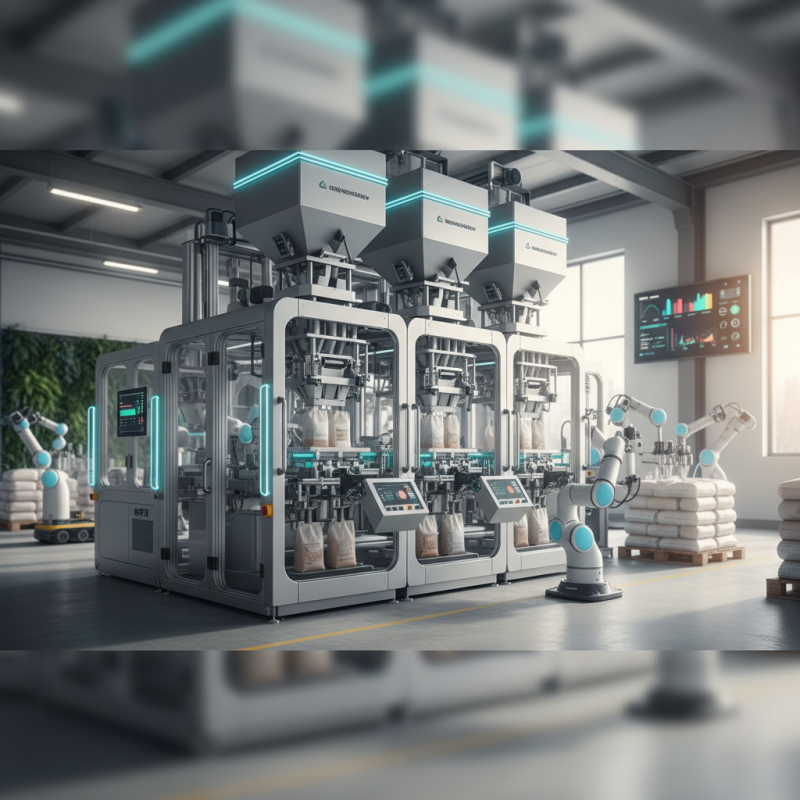

Top 2025 Automated Bagging Systems: Benefits, Trends, and Innovations

In the rapidly evolving landscape of industrial automation, automated bagging systems have emerged as a cornerstone for optimizing operational efficiency and enhancing productivity across various sectors. These systems streamline the packaging process by automating the filling, sealing, and labeling of bags, which significantly reduces labor costs and minimizes the risk of human error. As companies strive to meet the demands of a dynamic market while maintaining quality and speed, the adoption of automated bagging systems is becoming increasingly prevalent.

Looking ahead to 2025, several key trends and innovations are poised to reshape the landscape of automated bagging systems. Advances in technology, such as artificial intelligence and machine learning, are enabling smarter and more adaptable bagging solutions that can respond to varying product types and production volumes. Additionally, sustainability initiatives are driving the development of eco-friendly packaging materials and processes within these systems, reflecting a growing commitment to environmental responsibility. As businesses seek to stay competitive, understanding the benefits and trends in automated bagging systems will be crucial for making informed investment decisions that align with their operational goals and sustainability objectives.

Top Benefits of Automated Bagging Systems in 2025

Automated bagging systems are becoming increasingly indispensable for industries looking to enhance their operational efficiency and reduce labor costs. In 2025, the adoption of these systems is expected to bring forth numerous benefits that will transform traditional packaging processes. One of the key advantages is the significant increase in throughput. Automated systems can operate continuously and quickly, allowing businesses to pack products at a much faster rate compared to manual labor. This not only speeds up production times but also helps meet the growing demand in various sectors, from food and beverage to pharmaceuticals.

Another noteworthy benefit is the improvement in product consistency and quality. Automated bagging systems minimize the risk of human error, ensuring that each bag is packed uniformly and accurately. This leads to higher-quality packaging, which can enhance brand reputation and customer satisfaction. Furthermore, these systems often come equipped with advanced technology, including sensors and software for monitoring and adjustments, that allows for real-time data collection and analysis. This capability helps companies optimize their operations, foresee maintenance needs, and make informed decisions based on analytics, ultimately leading to cost savings and increased profitability.

Key Trends Shaping the Future of Automated Bagging Technology

The landscape of automated bagging technology is evolving rapidly, influenced by a variety of key trends that are shaping the future of the industry. One significant trend is the integration of artificial intelligence and machine learning into bagging systems. According to a recent report by MarketsandMarkets, the global market for automated bagging solutions is projected to grow from $2.1 billion in 2023 to $3.5 billion by 2025. This surge is partly driven by the increasing demand for precision and efficiency in packaging processes, enabling manufacturers to reduce operational costs and improve overall productivity.

Another trend reshaping the automated bagging industry is the rise of sustainability initiatives. With environmental concerns gaining traction, companies are increasingly focusing on eco-friendly packaging solutions. A study by Grand View Research highlights that 67% of consumers prefer brands that offer sustainable packaging. This trend is prompting manufacturers to innovate with biodegradable and recyclable materials in their bagging processes, ensuring compliance with global sustainability goals while appealing to environmentally conscious consumers.

Tips: When considering automated bagging systems, evaluate the potential for integration with existing operations. Prioritize solutions that offer adaptability to different product types and sizes. Additionally, keep an eye on emerging technologies that can enhance quality control and reduce waste, ensuring your operations remain ahead of the curve in this rapidly evolving market.

Innovations Driving Efficiency in Automated Bagging Solutions

Automated bagging systems are undergoing significant innovations that are enhancing operational efficiency across various industries. One of the key trends driving this evolution is the integration of advanced robotics and artificial intelligence. These technologies enable machines to perform complex tasks with precision and speed, reducing the need for manual labor and minimizing human error. As a result, facilities can achieve much higher throughput while maintaining consistent quality in their packaging processes.

Another noteworthy innovation is the adoption of smart sensors and IoT connectivity. By equipping bagging systems with sensors, companies can monitor performance in real-time, leading to proactive maintenance and reduced downtime. This connectivity allows for data-driven decision-making, where businesses can analyze packing patterns and optimize workflows. Furthermore, machine learning algorithms can predict potential issues before they arise, ensuring that the systems operate at peak efficiency without unexpected disruptions. Overall, these advancements are transforming automated bagging solutions into smarter, more reliable systems that align with the demands of modern manufacturing and packaging operations.

Market Analysis: Growth Statistics for Automated Bagging Systems

The automated bagging systems market is experiencing significant growth, driven by advancements in technology and increasing demand for efficiency in packaging operations. As industries recognize the need to optimize labor costs and enhance productivity, automated solutions are becoming indispensable. Recent statistics indicate that the global market for automated bagging systems is projected to expand substantially over the next few years, with a compound annual growth rate (CAGR) that reflects a robust interest from various sectors, including food and beverage, pharmaceuticals, and e-commerce.

In addition to improving operational efficiency, automated bagging systems offer numerous benefits that contribute to their growing popularity. Enhanced accuracy in the packaging process reduces waste and minimizes errors, which is crucial for maintaining quality standards. Moreover, the integration of smart technologies, such as artificial intelligence and machine learning, is transforming these systems by enabling predictive maintenance and real-time monitoring. This technological evolution not only streamlines workflow but also supports sustainable practices by optimizing resource usage. As companies continue to invest in automation, the future of bagging systems is poised for innovative breakthroughs that align with market demands.

Challenges and Solutions in Adopting Automated Bagging Systems

The adoption of automated bagging systems faces several challenges that businesses must navigate to reap their benefits fully. One primary issue is the initial investment cost associated with acquiring advanced technology. Many organizations hesitate to commit significant financial resources, fearing that the potential return on investment may not justify the expenses. To mitigate this, companies can consider phased implementations or leasing options, which allow them to gradually adopt automation without overwhelming their budgets. Moreover, ensuring a thorough evaluation of potential system impacts on workflow can guide businesses in making informed decisions that align with their long-term operational goals.

Another critical challenge revolves around the workforce's skill set. As automation technologies evolve, there is a growing need for skilled labor capable of operating and maintaining these systems effectively. This shift can lead to employee resistance or concerns about job security. Companies can address this challenge through comprehensive training programs that empower existing staff with the necessary skills and encourage their involvement in the automation process. Ensuring open communication about the benefits of automation can foster a culture of collaboration, easing the transition and helping workers adapt to new roles in an increasingly automated environment.

Top 2025 Automated Bagging Systems: Benefits and Adoption Challenges

Related Posts

-

Maximizing Efficiency: Innovative Bagging Systems Transforming Packaging Solutions

-

Unlocking Efficiency: How Automated Bagging Systems Boost Packaging Speeds by 40% in 2023

-

Revolutionizing E-commerce: How Automated Packaging Enhances Delivery Efficiency and Customer Satisfaction

-

How to Choose the Right Industrial Packaging Equipment for Your Business Needs

-

Top 5 Bagging Machines for Efficient Packaging Solutions in 2023

-

How to Choose the Right Automated Packaging Solutions for Your Business