NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

2025 Top Industrial Packaging Machines Trends and Innovations You Should Know

The landscape of industrial packaging machines is rapidly evolving, driven by the need for efficiency, sustainability, and innovation. As businesses face increasing pressure to optimize their operations, the demand for advanced packaging solutions is at an all-time high. According to a recent report by MarketsandMarkets, the industrial packaging market is projected to grow from USD 66.68 billion in 2020 to USD 81.66 billion by 2025, highlighting the critical role these machines play in production and distribution.

Industry experts suggest that the ongoing advancements in automation and technology will significantly shape the future of industrial packaging. John Smith, an established authority in packaging technology, states, "The integration of smart technology in industrial packaging machines not only enhances operational efficiency but also builds resilience against supply chain disruptions." This sentiment echoes throughout the industry, as companies increasingly prioritize innovations that align with their operational goals and customer demands.

As we look towards 2025, several key trends and innovations will emerge that promise to redefine the capabilities of industrial packaging machines. From developments in eco-friendly materials to the incorporation of AI and machine learning, staying informed of these trends is essential for businesses aiming to remain competitive in this dynamic market.

Emerging Technologies Shaping Industrial Packaging Machines in 2025

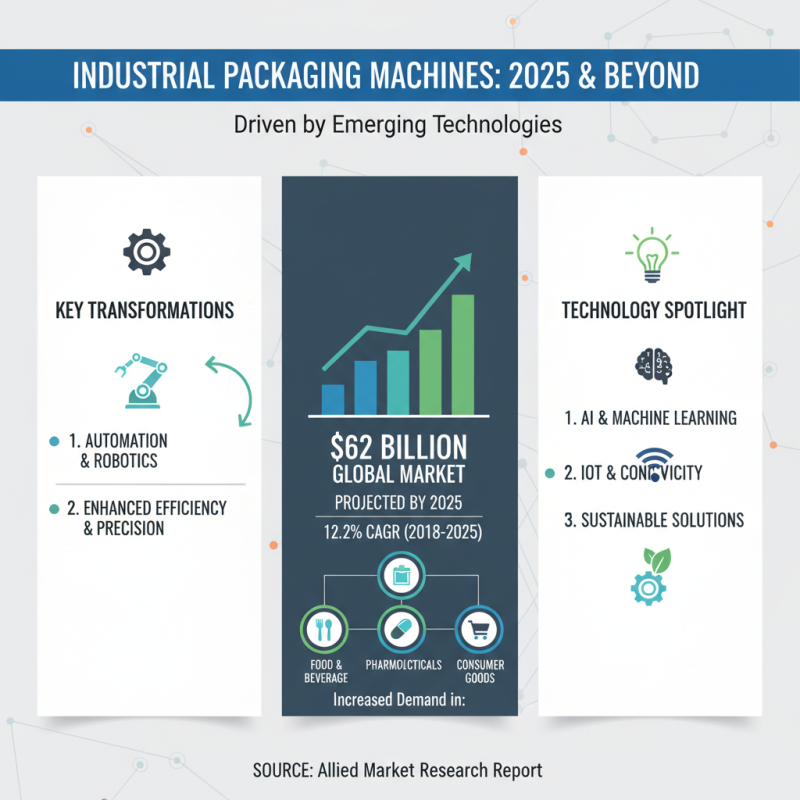

The landscape of industrial packaging machines is set to undergo significant transformation by 2025, driven by a multitude of emerging technologies. Automation and robotics are at the forefront, offering unprecedented efficiency and precision in packaging operations. According to a report by Allied Market Research, the global market for automated packaging machines is projected to reach $62 billion by 2025, representing a CAGR of 12.2% from 2018. This surge is largely attributed to the increasing demand for streamlined processes in industries such as food and beverage, pharmaceuticals, and consumer goods.

Moreover, advancements in artificial intelligence (AI) and machine learning are revolutionizing how packaging machines are designed and operated. These technologies allow for real-time data analysis, predictive maintenance, and improved supply chain logistics. A study by Technavio indicates that the adoption of AI in packaging could reduce operational costs by up to 30%, enhancing both productivity and sustainability. Furthermore, innovations such as smart packaging, which incorporates IoT devices, are enabling manufacturers to monitor product integrity and environmental conditions, thereby ensuring quality and compliance throughout the supply chain.

As we look ahead, the integration of sustainable practices will also play a crucial role in shaping the future of industrial packaging machines. The demand for eco-friendly materials and processes is increasing, with the global sustainable packaging market estimated to surpass $500 billion by 2027, as reported by MarketsandMarkets. This shift not only underscores the industry's responsiveness to consumer preferences but also signals a broader commitment to reducing environmental impact, further driving innovation in packaging technologies.

Sustainable Materials and Their Impact on Packaging Innovation

As the industrial packaging landscape evolves, sustainable materials are increasingly recognized as pivotal to innovation. A recent report by Smithers Pira highlights that the global market for sustainable packaging is projected to reach $280 billion by 2025, driven by a growing demand for eco-friendly solutions. This surge is not merely a trend but rather a necessity as companies strive to reduce their environmental footprints. Innovations in bioplastics, recycled materials, and renewable resources are at the forefront, offering manufacturers the ability to create effective packaging that is both functional and environmentally responsible.

Moreover, the integration of sustainable materials into industrial packaging is transforming supply chains. According to a 2022 study by the Ellen MacArthur Foundation, adopting circular economy principles could yield as much as $1 trillion in economic benefits while significantly decreasing waste. Businesses are now prioritizing the use of renewable and biodegradable materials which not only meet regulatory standards but also appeal to increasingly eco-conscious consumers. In this evolving landscape, companies embracing these sustainability-centric innovations are positioning themselves as leaders in an industry that is gravitating towards a more circular future.

2025 Trends in Industrial Packaging Machines: Sustainable Materials Overview

Automation Trends in Industrial Packaging Machinery for Efficiency

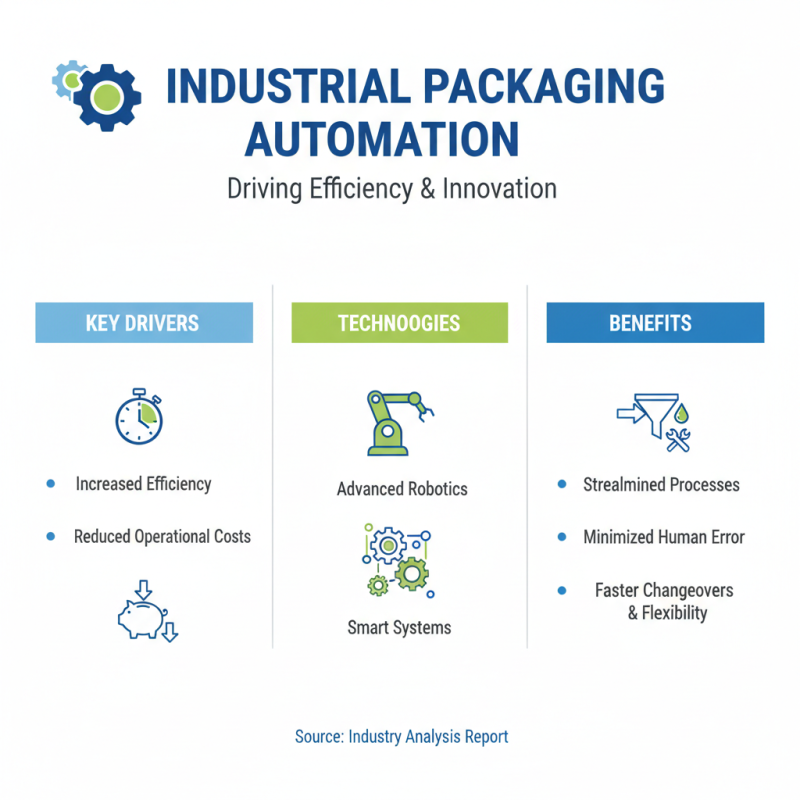

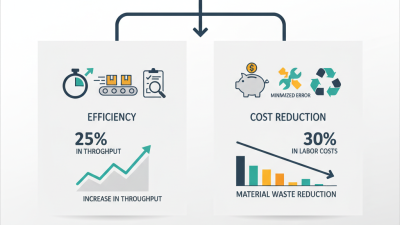

The industrial packaging machinery sector is experiencing a significant transformation driven by automation. As companies strive for increased efficiency and reduced operational costs, automation technologies are at the forefront of innovation. By implementing advanced robotics and smart systems, manufacturers can streamline their packaging processes, minimize human error, and enhance throughput. These automated solutions allow for faster changeovers and greater flexibility, enabling businesses to respond more swiftly to market demands.

Moreover, the integration of Internet of Things (IoT) technologies into packaging machines is revolutionizing data management and decision-making. With real-time data analytics, companies can monitor performance metrics and identify bottlenecks in their production lines. This data-driven approach not only optimizes machine utilization but also contributes to predictive maintenance, resulting in reduced downtime and enhanced productivity. As automation continues to evolve, the packaging industry is likely to see even more sophisticated solutions that cater to diverse operational needs while maintaining product quality and safety.

Integrating IoT and Smart Features in Packaging Solutions

The integration of the Internet of Things (IoT) and smart features into industrial packaging machines presents a significant trend for the future of packaging solutions. As industries strive for enhanced efficiency and sustainability, the incorporation of IoT technology allows for real-time monitoring and data collection along the production line. According to a recent report by Smithers, the global demand for smart packaging is expected to reach $45 billion by 2025, highlighting the rapid adoption of these technologies across various sectors.

Smart features, such as automated quality control and predictive maintenance, contribute to reducing downtime and waste in packaging operations. A study by Grand View Research projects that the smart packaging market will grow at a CAGR of 7.4% over the next few years, fueled by innovations such as sensors that can monitor temperature and humidity conditions, ensuring product integrity. Moreover, adopting smart packaging solutions enables manufacturers to respond swiftly to market demands, optimizing supply chain logistics and improving overall productivity.

Furthermore, the data collected through IoT devices can support better decision-making processes, allowing companies to analyze trends and customer preferences. By leveraging this information, businesses can streamline their packaging processes, adapt to changing consumer behavior, and enhance the overall user experience. This proactive approach not only boosts operational efficiency but also aligns with the growing emphasis on sustainability in packaging practices, paving the way for further advancements in the industrial packaging sector.

2025 Top Industrial Packaging Machines Trends and Innovations You Should Know

| Trend/Innovation | Description | Impact on Industry | Expected Adoption Rate (%) |

|---|---|---|---|

| IoT Integration | Utilizing IoT technology to monitor packaging conditions and improve supply chain transparency. | Increased efficiency and reduction of waste, enabling proactive maintenance. | 75% |

| Smart Sensors | Integration of sensors that can detect temperature, humidity, and other environmental factors. | Enhances product safety and quality assurance during transport. | 70% |

| Robotic Automation | Deployment of robotic systems for packing, palletizing, and sorting processes. | Increases throughput and reduces manual labor costs. | 60% |

| Sustainable Packaging | Focus on eco-friendly materials and processes in packaging design. | Reduces environmental impact and meets consumer demand for sustainability. | 80% |

| Blockchain for Traceability | Using blockchain technology to secure the supply chain and enhance traceability of products. | Improves transparency and consumer trust in products. | 65% |

Future-Proofing Packaging with Modular and Flexible Machine Designs

As the industrial packaging landscape evolves, the emphasis on modular and flexible machine designs has become crucial for future-proofing operations. Flexibility in packaging machinery allows companies to adapt swiftly to changing market demands and diverse product specifications. According to a recent report by Smithers Pira, the global market for flexible packaging is projected to reach approximately $320 billion by 2025, highlighting a significant shift toward adaptable packaging solutions capable of accommodating various products and volumes. This trend underscores the necessity for equipment that can be easily modified or reconfigured, enabling manufacturers to respond to fluctuations in consumer demand without incurring substantial downtime or additional costs.

Moreover, adopting modular designs in packaging machinery promotes efficiency and sustainability. A modular system allows companies to upgrade or replace specific components without overhauling the entire machine, effectively reducing waste and prolonging the life cycle of equipment. The Freedonia Group predicts that the market for industrial packaging machines will grow at a compound annual growth rate (CAGR) of 4.7% through 2025, driven in part by the increasing demand for sustainability and efficiency in production processes. By integrating modular and flexible designs, businesses not only enhance their operational agility but also align with the broader industry push towards environmentally friendly practices, positioning themselves competitively in a rapidly evolving market.

Related Posts

-

Top 10 Industrial Packaging Machines Transforming Efficiency with 2023 Data

-

Why Industrial Packaging Machines Are Essential for Modern Manufacturing Success

-

Benefits of Automated Packaging for Efficiency and Cost Reduction

-

Revolutionize Your Packaging Process with Innovative Bag Filling Equipment Solutions

-

How to Choose the Right Industrial Packaging Equipment for Your Business Needs

-

Revolutionizing E-commerce: How Automated Packaging Enhances Delivery Efficiency and Customer Satisfaction