NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Best Automated Bagging Systems for Efficient Packaging Solutions

In the fast-paced world of manufacturing and logistics, efficiency is paramount, and the ability to streamline packaging processes can significantly impact overall productivity. Automated bagging systems have emerged as a vital solution for businesses aiming to optimize their packaging lines. According to a report by Smithers Pira, the automation of packaging processes can result in a reduction of labor costs by up to 20%, highlighting the importance of integrating technology in traditional systems.

Moreover, the global automated packaging market is projected to reach $85 billion by 2027, with a significant portion attributed to advancements in automated bagging systems. These systems not only enhance speed and accuracy but also improve consistency in packaging, which is crucial for maintaining product integrity and reducing spoilage. By implementing these automated solutions, companies can meet the growing demands of consumers while minimizing errors and waste.

As industries continue to evolve, the adoption of automated bagging systems represents a strategic move towards smarter, more efficient operations. Businesses recognizing these trends are positioning themselves to leverage the benefits of automation, ensuring they remain competitive in an increasingly challenging market landscape.

Best Automated Bagging Systems for Efficient Packaging Solutions

Automated bagging systems have become essential tools in various industries seeking to enhance their packaging processes. These systems are designed to streamline the packaging workflow, significantly reducing the time and labor required compared to manual methods. By integrating advanced technology, such as sensors and robotics, automated bagging systems can accurately fill and seal bags, ensuring consistency and efficiency in the packaging operation. This not only boosts productivity but also minimizes the risk of human error, leading to more reliable product presentation.

In addition to efficiency, automated bagging solutions offer flexibility to accommodate different bag sizes and materials, making them suitable for a wide range of products. Manufacturers can easily adjust their setup to handle anything from small sachets to large bulk bags, catering to diverse market demands. Furthermore, modern systems come equipped with features like real-time monitoring and data analytics, providing valuable insights into production performance and helping businesses optimize their operations. By investing in automated bagging systems, companies can achieve significant improvements in their packaging processes, contributing to overall operational success.

Overview of Automated Bagging Systems in Modern Packaging

Automated bagging systems have emerged as a crucial component in the modern packaging industry, optimizing production lines and enhancing efficiency. According to a report from Research and Markets, the global automated bagging system market is projected to reach USD 6.2 billion by 2025, growing at a CAGR of 5.6% over the next few years. This growth is driven by the increasing demand for packaged goods and the need for efficient, cost-effective solutions that minimize labor costs while ensuring high-speed packaging.

The evolution of automated bagging technology has led to significant improvements in packaging speed and precision. For instance, advanced systems can package products at rates exceeding 30 bags per minute, reducing manual handling and the risk of errors. Furthermore, the integration of machine learning and artificial intelligence in these systems allows for adaptive packaging processes that can adjust to varying product specifications in real-time. According to a study by PMMI, over 60% of manufacturers reported enhanced productivity levels after implementing automated solutions, highlighting the impact of these systems on operational efficiency and overall output.

As companies strive to meet sustainability goals, automated bagging systems also offer opportunities for eco-friendly packaging options. The ability to use biodegradable materials and optimize the use of packaging resources aligns with the growing trend towards sustainability in the packaging sector. With the combined benefits of cost reduction, efficiency, and sustainability, automated bagging systems are becoming indispensable for companies seeking to stay competitive in today’s fast-paced market.

Key Features and Technologies of Automated Bagging Machines

Automated bagging machines are revolutionizing the packaging industry by enhancing efficiency and accuracy in the packing process. These advanced systems are equipped with an array of key features, including high-speed filling capabilities, programmable logic controllers (PLCs), and user-friendly interfaces. The integration of sensors and weight scales ensures precision in measuring and filling, thus minimizing wastage and ensuring product quality.

When evaluating the best automated bagging systems, it’s important to consider the scalability of the technology. Systems that can easily adapt to various bag sizes and materials will offer greater flexibility in production. Additionally, look for machines that incorporate advanced technologies like robotics for quicker handling and seamless integration with other production line equipment.

**Tip:** Regular maintenance of your automated bagging system can greatly enhance its longevity and performance. Make sure to keep the machine clean and schedule periodic checks on the sensors and software updates.

Furthermore, the use of artificial intelligence in automated bagging systems is on the rise. AI-enhanced machines can analyze production data in real time, optimizing the packing process and reducing the likelihood of errors. This ensures a smoother workflow, particularly in high-demand environments where speed is critical.

**Tip:** Always ensure that your team is well trained in operating and troubleshooting the automated bagging system to maximize efficiency and minimize downtime.

Industry Statistics: Market Growth and Adoption Rates of Bagging Systems

The automated bagging systems market has experienced significant growth over the past few years, driven by increased demand for efficient packaging solutions across various industries, including food and beverage, pharmaceuticals, and e-commerce. According to a recent report by Grand View Research, the global automated bagging systems market was valued at approximately $1.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of around 6.9% from 2023 to 2030. This growth can be attributed to the rising emphasis on operational efficiency and automation in manufacturing processes.

Furthermore, adoption rates of automated bagging systems continue to rise as companies recognize the benefits of reducing labor costs and improving packaging accuracy. A survey conducted by Packaging Strategies indicated that 54% of manufacturers are now incorporating automated solutions to meet the demands of high-volume production. The increased integration of smart technologies, such as IoT and artificial intelligence, into bagging systems further enhances their efficiency, providing real-time data analytics and performance monitoring. This trend reflects a broader shift toward automation in logistics and supply chain management, highlighting the vital role these systems play in meeting modern packaging needs.

Case Studies: Successful Implementation of Automated Bagging Solutions

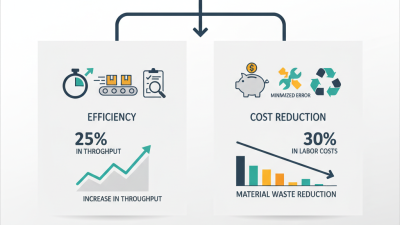

The implementation of automated bagging systems has proven to enhance operational efficiency across various industries. For instance, a case study in the food packaging sector revealed that a company reduced its packaging cycle time by 30% after integrating an automated bagging solution. According to a report by Research and Markets, the global automated packaging market is anticipated to reach $70 billion by 2027, highlighting the increasing reliance on automation in packaging processes. This significant growth is largely driven by the demand for faster and more reliable packaging, allowing companies to keep pace with the competitive market.

Another successful example can be found in the consumer goods industry, where a leading manufacturer reported a 25% decrease in labor costs following the deployment of an automated bagging system. This system not only streamlined the workflow but also minimized manual errors, resulting in improved product quality and consistency. The International Society for Automation noted that companies adopting automation can achieve a return on investment (ROI) within 18 months, often due to reduced labor and material costs. Such case studies emphasize how automated bagging solutions not only improve efficiency but also yield tangible financial benefits, making them an attractive option for businesses aiming for operational excellence.

Conclusion

Automated bagging systems have become essential in modern packaging, enhancing efficiency and accuracy across various industries. These advanced machines incorporate key features and technologies such as precision filling, high-speed sealing, and smart integration with existing production lines. Their adoption has led to significant market growth, driven by a demand for cost-effective and scalable packaging solutions.

Case studies demonstrate successful implementations of automated bagging solutions, where businesses have experienced improved productivity and reduced labor costs. Looking ahead, future trends indicate a focus on innovations that prioritize sustainability, such as eco-friendly materials and energy-efficient operations. As the industry evolves, automated bagging systems are set to play a crucial role in shaping the future of packaging.

Related Posts

-

Unlocking Efficiency: How Automated Bagging Systems Boost Packaging Speeds by 40% in 2023

-

Revolutionizing E-commerce: How Automated Packaging Enhances Delivery Efficiency and Customer Satisfaction

-

2025 How to Optimize Your Packaging Automation for Maximum Efficiency

-

How to Choose the Right Automated Packaging Solutions for Your Business

-

Benefits of Automated Packaging for Efficiency and Cost Reduction

-

The Future of Packaging Machines Innovations Transforming the Industry