NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Benefits of Automated Packaging for Efficiency and Cost Reduction

The advent of automated packaging has revolutionized the manufacturing and logistics landscape, offering significant advantages in terms of efficiency and cost reduction. According to a recent report by the Packaging Automation Association, businesses that implement automated packaging systems can achieve up to a 30% reduction in labor costs and a 25% increase in throughput. This transformation is largely attributed to the ability of automated systems to streamline production processes, minimize human error, and optimize resource utilization. As industries strive for operational excellence, the demand for innovative packaging solutions continues to grow.

In the context of evolving market demands and competitive pressures, automated packaging not only enhances efficiency but also contributes to sustainability efforts. The World Packaging Organization highlights that automation can lead to a reduction in material wastage by up to 20% due to precise filling and sealing processes. Furthermore, automated systems are designed to adapt to different packaging formats and sizes with minimal downtime, making them an ideal solution for businesses facing fluctuating consumer preferences. By incorporating automated packaging, companies can not only meet their cost-saving targets but also position themselves favorably in an increasingly eco-conscious market.

Advantages of Automated Packaging in Modern Manufacturing

Automated packaging is transforming the landscape of modern manufacturing, offering numerous advantages that significantly enhance operational efficiency. According to a report by Smithers Pira, the global market for automated packaging solutions is projected to reach $6.8 billion by 2024, highlighting the growing recognition of its benefits. One primary advantage is the reduction in labor costs; automation can cut labor requirements by up to 30%, allowing companies to allocate resources more effectively. Furthermore, automated systems can maintain a consistent level of output, increasing production rates by as much as 40% compared to manual processing.

In addition to cost savings, automated packaging improves accuracy and reduces waste. A study from the Association for Packaging and Processing Technologies indicated that automated systems could reduce packaging errors by over 90%, enhancing product quality and customer satisfaction. This level of precision not only minimizes material wastage but also streamlines supply chain operations, which are critical in today’s fast-paced market. As manufacturers continue to embrace automation, the integration of advanced technologies such as artificial intelligence and machine learning will further drive efficiency, paving the way for innovative solutions that cater to increasing consumer demands.

Benefits of Automated Packaging for Efficiency and Cost Reduction

| Benefit | Description | Impact on Efficiency | Impact on Cost |

|---|---|---|---|

| Increased Speed | Automated systems can package products at a faster rate than manual labor. | High | Reduces labor costs |

| Consistency and Quality | Automated packing reduces errors, ensuring consistent packaging quality. | Medium | Minimizes waste and rework costs |

| Labor Savings | Reduces the need for manual packaging labor. | High | Substantial reductions in labor costs |

| Scalability | Easy to scale operations up or down based on demand. | High | Improves overall operational cost efficiency |

| Enhanced Safety | Reduces the risk of injuries associated with repetitive packing tasks. | Medium | Lowers potential costs from workplace accidents |

Enhancing Operational Efficiency through Automation

Automated packaging systems have become essential in modern manufacturing, significantly enhancing operational efficiency. According to a report by the Automation World, implementing automation in packaging processes can lead to a 20-30% increase in productivity. This improvement often stems from the reduction of manual labor, which not only speeds up production times but also minimizes human error, thereby increasing the accuracy and quality of packaged goods. As companies embrace automation, they can allocate human resources to more strategic tasks, ultimately leading to a more agile and responsive operational framework.

Moreover, the financial implications of automated packaging are substantial. A study from the Packaging Machinery Manufacturers Institute (PMMI) indicates that companies utilizing integrated automated systems can experience up to a 25% reduction in operational costs. This cost-effectiveness results from decreased labor expenses, lower material waste due to precise packaging, and improved equipment efficiency. When paired with real-time data analytics, automated packaging solutions present businesses with valuable insights that enhance decision-making processes and streamline supply chain management, allowing businesses to adapt quickly to market demands while maintaining competitive pricing.

Cost Reduction Strategies in Automated Packaging Systems

Automated packaging systems are revolutionizing the way businesses approach cost reduction. One of the most significant strategies is the minimization of labor costs. By implementing automated solutions, companies can reduce their reliance on manual labor, thus decreasing the expenses related to hiring, training, and maintaining a workforce. This shift not only lowers overhead costs but also enhances operational efficiency, as machines can operate continuously without the need for breaks or downtime associated with human workers.

Another critical strategy lies in optimizing material usage. Automated packaging systems are designed to precise specifications, which reduces waste significantly. By cutting down on excess packaging materials and utilizing recyclable options, companies can not only lower their material costs but also enhance their sustainability efforts. Furthermore, incorporating real-time data analytics allows businesses to monitor packaging processes, adjusting to fluctuations in demand and material requirements, which leads to better inventory management and reduced costs associated with overproduction.

Finally, enhanced tracking and automation reduce errors in the packaging process. By minimizing mistakes, companies save on costs related to rework and product returns. The integration of automated quality control can catch defects early in the production line, ensuring that only the best products reach the consumer. This proactive approach not only streamlines the packaging process but also builds customer trust, as fewer errors translate to higher satisfaction and loyalty.

Impact of Automated Packaging on Labor and Resource Management

The implementation of automated packaging significantly transforms labor and resource management within various industries. By streamlining processes, businesses can reduce the dependency on manual labor, which not only decreases the costs associated with hiring and training employees but also mitigates human errors in packaging operations. This shift allows companies to redirect their workforce towards more strategic roles, enhancing overall productivity and job satisfaction.

Moreover, automated packaging systems contribute to more efficient resource management. These systems are often designed to minimize material waste through precise measurements and optimized use of packaging materials. This efficiency not only lowers costs related to purchasing materials but also supports sustainability efforts by reducing the environmental footprint of packaging operations. Additionally, with real-time monitoring and data analysis capabilities, businesses can better manage inventory and forecast resource needs, leading to smarter decision-making and reduced operational downtime.

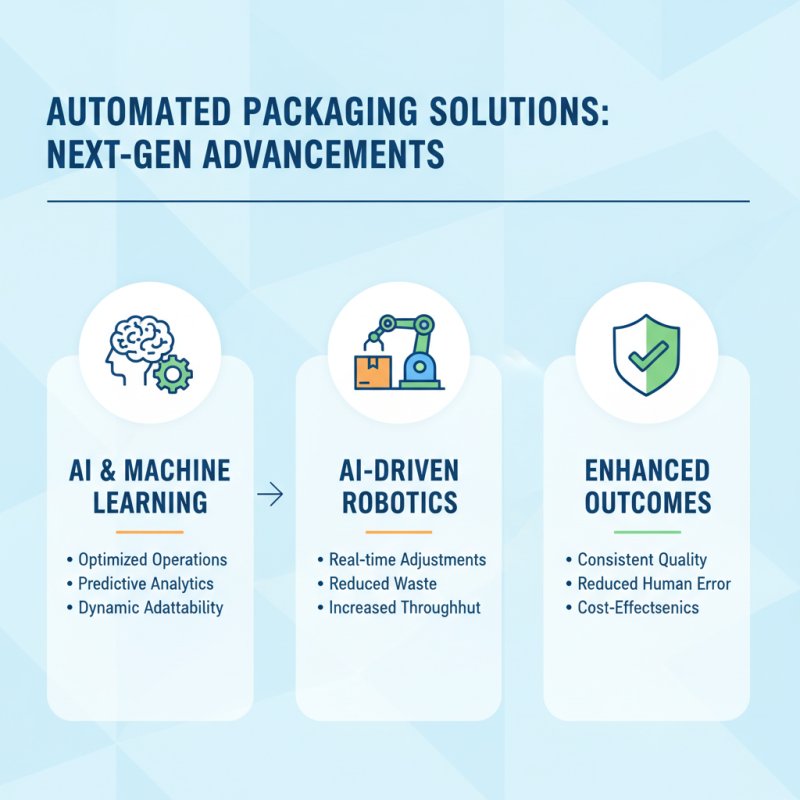

Technological Innovations Driving Automated Packaging Solutions

Automated packaging solutions have seen rapid advancements due to various technological innovations that enhance both efficiency and cost-effectiveness in manufacturing processes. These innovations include the integration of artificial intelligence (AI) and machine learning, which enable systems to learn from data patterns and optimize operations dynamically. For instance, AI-driven robotics can adjust their packaging speed and techniques in real-time based on product variations, minimizing waste and maximizing throughput. This adaptability not only streamlines the packaging process but also reduces the likelihood of human error, ensuring consistent quality.

In addition to AI, the incorporation of advanced sensors and IoT (Internet of Things) connectivity has transformed automated packaging lines. These technologies facilitate real-time monitoring of packaging machinery, allowing for predictive maintenance and reducing downtimes significantly. By collecting data on equipment performance and product handling, companies can identify potential issues before they escalate, leading to substantial cost savings. Moreover, the ability to track products through the supply chain enhances transparency and optimizes inventory management, further bolstering the overall efficiency of automated packaging solutions.

Related Posts

-

How to Choose the Right Automated Packaging Solutions for Your Business

-

Unlocking Efficiency: How Automated Bagging Systems Boost Packaging Speeds by 40% in 2023

-

Revolutionizing E-commerce: How Automated Packaging Enhances Delivery Efficiency and Customer Satisfaction

-

The Future of Packaging Machines Innovations Transforming the Industry

-

2025 How to Optimize Your Packaging Automation for Maximum Efficiency

-

Top 5 Automated Filling Machines for Efficient Production in 2023