NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Top Automated Packaging System Solutions for Your Business Needs?

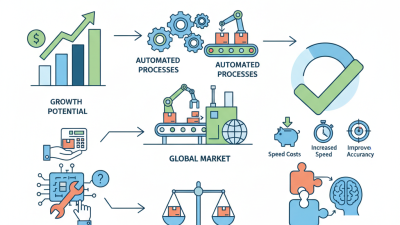

In today’s fast-paced market, businesses seek efficiency and reliability. An "automated packaging system" plays a crucial role in achieving these goals. John Smith, a renowned expert in packaging technology, once said, "Automation is no longer optional; it’s essential for survival." His insight captures the urgency felt by many companies.

Automated packaging systems streamline operations, reduce labor costs, and enhance product protection. However, selecting the right solution can be daunting. The market is flooded with options, each promising unique benefits. The wrong choice can lead to wasted resources and inefficiencies.

Understanding your specific needs before investing is vital. A tailored approach to packaging ensures better alignment with company goals. Many businesses overlook this aspect and regret hasty decisions. As automation becomes more advanced, continuous reflection on choices made will remain crucial for long-term success.

Overview of Automated Packaging Systems: Key Features and Benefits

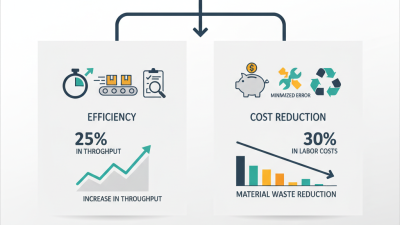

Automated packaging systems play a crucial role in modern businesses. They offer efficiency and accuracy. According to a recent industry survey, 75% of packaging companies report improved productivity after implementing these systems. This shift often leads to significant cost savings. Labor costs can decrease by up to 30% when automation takes over repetitive tasks.

Key features of these systems include speed, precision, and adaptability. They can work seamlessly with various packaging materials, from boxes to flexible pouches. Real-time data tracking allows for immediate adjustments. However, not every business can manage this technology easily. A study found that 40% of companies face integration challenges. Training staff can also be time-consuming.

Benefits extend beyond just cost savings. Automated systems reduce waste through optimized material usage. They also enhance safety by minimizing manual handling. A report noted that accidents related to packaging tasks dropped by 20% in automated environments. Yet, realizing these benefits doesn’t come without effort. Some companies may struggle during the transition phase. Planning and support are essential for success.

Types of Automated Packaging Solutions: Finding the Right Fit for Your Business

Automated packaging solutions have transformed the logistics landscape. Choosing the right type depends on specific business needs. For example, semi-automated systems are suitable for small to medium operations. They can enhance efficiency while keeping costs manageable. Industry reports indicate that these solutions can increase packaging speed by up to 50%. This kind of efficiency is essential for meeting growing market demands.

Fully automated systems are ideal for larger operations. They handle high-volume production with minimal labor. However, the initial investment can be significant. Reports show that while a fully automated line can reduce labor costs by over 30%, configuring and maintaining these systems requires expertise. Not all businesses may find the ROI justifiable.

Consideration of sustainability is also vital. Some automated solutions integrate eco-friendly materials. This helps businesses meet corporate social responsibility goals. However, transitioning to greener packaging can present challenges. It requires rethinking existing procedures and supply chains. Balancing efficiency, cost, and sustainability is not easy but essential in today's market.

Top Automated Packaging System Solutions for Your Business Needs

This chart displays the different types of automated packaging solutions and their effectiveness based on various business needs. Each type serves specific requirements, aiding in better decision-making for your packaging operations.

Factors to Consider When Selecting an Automated Packaging System

Selecting an automated packaging system can be challenging. There are many factors to think about. One crucial aspect is the type of products you package. Different products may require different packaging solutions. For instance, fragile items need more protective packaging. Additionally, weight and size influence your choice.

Another factor is production volume. A business with high output may need a faster system. Speed ensures efficiency and meets customer demands. However, purchasing high-speed equipment without proper planning can lead to bottlenecks. Make sure to evaluate your workflow and current capacity.

Cost is always a concern. Automated systems often require substantial investment upfront. It’s important to assess your budget while considering long-term savings. Maintenance and operational costs also add up over time. A cheaper system may seem appealing but could lead to higher costs later on. Take time to reflect on your unique needs before making a decision.

Top Automated Packaging System Solutions for Your Business Needs

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Efficiency | Automated systems can operate continuously without need for frequent breaks, increasing overall output. | Higher production rates, reduced downtime. | Initial setup costs may be high. |

| Flexibility | Modern systems can be reprogrammed for different packing sizes and materials, making them adaptable to changing needs. | Ability to switch product lines without significant delays. | May require additional training for staff. |

| Cost-Effectiveness | Over time, automation can reduce labor costs and minimize waste. | Lower operating costs and improved profit margins. | Initial investment can be significant; ROI might take time. |

| Quality Control | Automated systems can incorporate real-time monitoring to ensure packaging meets quality standards. | Consistent packaging quality enhances brand reputation. | Dependence on technology may lead to issues if malfunctions occur. |

| Ease of Use | Most modern systems come with user-friendly interfaces and are designed for ease of operation. | Reduced training time for operators. | Complex systems can still present a learning curve. |

Cost Analysis: Budgeting for Your Automated Packaging Needs

When considering automated packaging solutions, budgeting is essential. Understand all associated costs, including equipment, installation, and maintenance. Identify your business’s specific needs to avoid overspending. Many businesses underestimate the long-term costs of operation, which can impact profitability.

Tips: Always plan for upgrades. As your business grows, so will your packaging needs. Investing in scalable systems can save money later. Monitor your usage patterns to assess efficiency. Sometimes, the cheapest option may lead to higher costs in the future.

Include unexpected expenses in your budget. These can arise from technical support or added training for your staff. It’s important to account for these factors to avoid financial strain. Additionally, a detailed cost analysis can help you make smarter decisions. Choosing a solution based solely on price may lead to a mismatch in performance. Always weigh the initial investment against potential savings.

Future Trends in Automated Packaging Technology and Innovation

The future of automated packaging technology is promising yet complicated. Innovations are driving efficiency and sustainability efforts. Eco-friendly materials are a key focus, reshaping how products are packaged. This shift can reduce waste significantly, but not all companies are ready. Balancing cost and sustainability remains a challenge.

Moreover, technology continues to advance rapidly. Robotics, artificial intelligence, and smart systems are revolutionizing packaging lines. These solutions enhance precision and speed, but they also require skilled operators. Training staff can be a hurdle for some businesses. Not all teams are equipped for this new landscape.

As businesses adopt these technologies, the integration process can be daunting. Some may struggle with transitioning from traditional methods. Additionally, the need for continuous updates can be challenging. While the future looks bright, adapting to these changes requires reflection and careful planning. The path toward full automation is exciting, but also fraught with uncertainties.

Related Posts

-

How to Implement Packaging Automation for Your Business?

-

Revolutionizing E-commerce: How Automated Packaging Enhances Delivery Efficiency and Customer Satisfaction

-

Unlocking Efficiency: How Automated Bagging Systems Boost Packaging Speeds by 40% in 2023

-

How to Choose the Right Automated Packaging Solutions for Your Business

-

Benefits of Automated Packaging for Efficiency and Cost Reduction

-

Best Automated Bagging Systems for Efficient Packaging Solutions