NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

What is a Bag Filling Machine and How Does It Work?

In the packaging industry, bag filling machines play a crucial role. These machines enhance efficiency and precision in filling bags with various products. According to industry expert James Harrington, “Bag filling machines streamline the packing process, saving time and reducing waste.” His insight underscores the significance of these machines.

Bag filling machines come in various types, designed for different needs. Some are automated, while others require manual operation. The typical operation involves fluffing the product, placing a bag on a spout, and filling it to the desired weight. However, not all machines achieve perfect results. Misalignment can lead to incorrect fills and wasted materials.

Proper maintenance is key to optimizing bag filling machines. Operators must regularly check the system for wear and tear. A neglected machine can lead to downtime or inefficiency. Addressing these issues requires a proactive approach. Mistakes in setup often occur, reminding us that continuous learning is essential in this field.

What is a Bag Filling Machine?

A bag filling machine is an essential tool in many industries. It automates the process of filling bags with products, enhancing efficiency. From food to chemicals, these machines cater to diverse needs. According to a recent market report, the global bag filling machine market is projected to reach $4.5 billion by 2025, underscoring its importance in manufacturing.

The operation of a bag filling machine is straightforward. Materials are loaded into the machine, which then dispenses a specific amount into each bag. This process can significantly reduce labor costs and improve accuracy. For example, these machines can fill bags at rates exceeding 50 bags per minute, depending on the product's nature.

Tips: Regular maintenance is crucial. Check for wear and tear on components to avoid unexpected downtime. In addition, ensure that you're using the correct settings for different materials. Improper settings can lead to inconsistent fills.

However, not all machines work perfectly. Some may struggle with various bag types or sizes. This can lead to issues such as spills or inaccurate fills. It's essential to assess your specific requirements before purchase. Investing time in understanding machine capabilities pays off in the long run.

The Importance of Bag Filling Machines in Industries

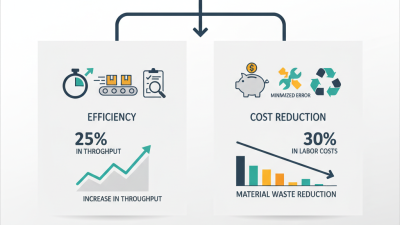

Bag filling machines are vital in various industries, from agriculture to pharmaceuticals. They streamline the packaging process, ensuring efficiency and consistency. According to a recent industry report, automated bag filling machines can increase production rates by over 30%. This boost in efficiency helps companies meet growing consumer demand with less labor.

The importance of these machines extends beyond mere speed. They enhance accuracy in measurements, reducing material waste. Industry studies show that businesses implementing advanced filling technologies can lower their operational costs by up to 20%. This saving is significant, especially for companies operating on tight margins. However, relying solely on automation can lead to issues, such as equipment malfunctions or inconsistent performance if not regularly maintained.

**Tip:** Regular maintenance of bag filling machines can prevent costly downtime.

Another aspect to consider is workforce training. Employees must understand how to operate these machines effectively. Without proper training, mistakes can occur, resulting in product losses. A comprehensive training program is essential.

**Tip:** Conduct periodic training refreshers to keep staff skills sharp.

In conclusion, while bag filling machines are crucial for modern manufacturing, the emphasis should be placed on both efficiency and human oversight to avoid pitfalls.

Importance of Bag Filling Machines in Various Industries

This chart illustrates the distribution of bag filling machine usage across different industries, highlighting their significance in enhancing efficiency and productivity.

How Bag Filling Machines Operate: A Step-by-Step Process

Bag filling machines are essential in many industries. They streamline the packaging process by efficiently filling bags with products. Understanding how these machines operate provides insight into their functionality.

To begin, the bag filling process starts with bag placement. A machine grabs an empty bag and positions it at the filling station. Next, the product flows into the bag through a channel or nozzle. This step seems straightforward, yet it requires precision. Improper alignment can cause spills. For smaller items, like grains, a vibratory feeder may help move them neatly into the bag.

Once the product reaches the desired weight, the bag is sealed. Various sealing methods may be used, such as heat sealing or stitching. However, mistakes can happen. Sometimes, bags may not seal properly. This oversight can lead to waste and product damage. Monitoring the machine closely during operation is crucial for maintaining quality control. Adjustments may be necessary to accommodate different bag types and sizes.

Types of Bag Filling Machines and Their Applications

Bag filling machines are crucial in various industries, including food, pharmaceuticals, and packaging. They automate the process of filling bags with products such as grains, powders, and liquids. The efficiency of these machines can significantly impact production rates and costs. According to a recent industry report, the global bagging machine market is expected to reach USD 4.5 billion by 2027, reflecting an annual growth rate of 5.4%. This growth is driven by the increasing demand for automation in manufacturing processes.

There are several types of bag filling machines available in the market. For instance, volumetric fillers are often used for dry products. These machines rely on a specific volume to dispense product, which can lead to discrepancies in filling weights. On the other hand, gravimetric filling machines weigh the product during the filling process, ensuring higher accuracy. However, these machines tend to be more complex and require regular calibration. A study indicated that nearly 30% of manufacturers struggle with maintaining this calibration, leading to possible product wastage.

Additionally, some machines are designed for specific applications. For example, vacuum packing machines are popular in the food industry to extend shelf life by removing air. Yet, operators sometimes overlook maintenance, which can lead to malfunctioning equipment. This highlights a common oversight in the industry—neglecting routine maintenance on essential machinery, impacting both efficiency and output. Balancing the types of machines used and maintaining them effectively can enhance overall productivity.

Key Features and Technologies in Modern Bag Filling Machines

Modern bag filling machines are remarkable in their efficiency and precision. They are designed to handle a variety of materials, from powders to granules. A key feature is the weighing system. It ensures each bag is filled accurately to avoid waste. Some machines use load cells, while others rely on volumetric measurements. The choice depends on the product's characteristics.

Another important technology is the automation aspect. Automated bag filling machines can operate with minimal human intervention. This not only speeds up production but also enhances safety. Most machines now come with touch screen interfaces, making them user-friendly. However, operators must be trained. Mistakes can lead to operational delays.

Flexibility is also a significant feature. Many machines can be adjusted for different bag sizes and weights. This adaptability is crucial for companies with diverse product lines. However, frequent adjustments can lead to calibration issues. Careful consideration is needed to maintain accuracy. The integration of smart technology into these systems is still a work in progress. Overall, advancements in bag filling technology are shaping the future of packaging, but challenges remain.

What is a Bag Filling Machine and How Does It Work? - Key Features and Technologies in Modern Bag Filling Machines

| Feature | Description | Technology Used |

|---|---|---|

| Automation | Automated systems reduce human labor and improve efficiency. | Programmable Logic Controllers (PLC) |

| Weighing and Filling | Accurate measurement of materials before filling. | Load Cells |

| Bag Feeding | Automatic feeding of empty bags into the filling station. | Conveyor Systems |

| Sealing Technology | Ensures that bags are securely closed after filling. | Heat Sealing, Ultrasonic Sealing |

| Data Integration | Connects with broader manufacturing software for data tracking. | IoT Connectivity |

| Customizable Options | Flexible design adapting to different bag types and sizes. | Modular Design |

Related Posts

-

Top 5 Bagging Machines for Efficient Packaging Solutions in 2023

-

How to Choose the Right Bagging Equipment for Your Needs?

-

Revolutionize Your Packaging Process with Innovative Bag Filling Equipment Solutions

-

Benefits of Automated Packaging for Efficiency and Cost Reduction

-

Top Material Handling Supplies for Improved Warehouse Efficiency

-

Understanding the Future of Industrial Packaging Innovations and Sustainability Trends