NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Exploring the Best Bag Filling Equipment of 2026 for Efficient Operations?

In 2026, the bag filling equipment industry is on the verge of significant advancement. According to recent market research by Smith & Associates, the global demand for bag filling machines is projected to reach $3 billion. This growth is driven by the rise in automation and efficiency in packaging operations across various sectors.

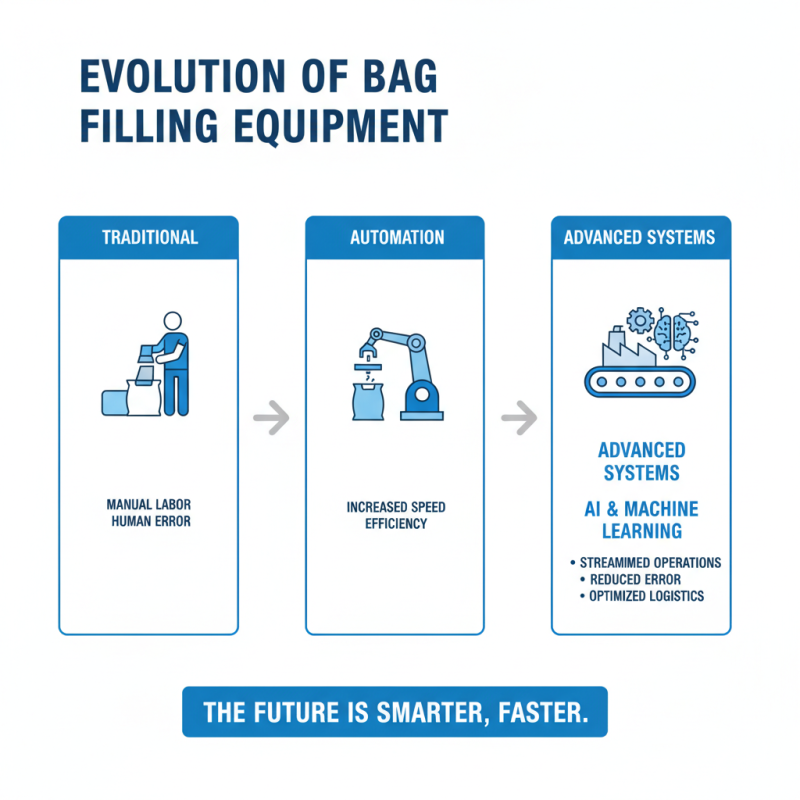

Industry expert Dr. Emily Chen highlights the importance of innovation in this field. "To stay competitive, manufacturers must invest in smarter bag filling technology," she states. Companies are increasingly seeking solutions that enhance speed and accuracy while minimizing waste. For instance, automated bagging systems now incorporate AI and machine learning. These technologies can adapt to varying product sizes and weights, leading to better performance.

Despite these advancements, challenges remain. Some facilities still rely on outdated equipment, resulting in inefficiencies. The need for training and adaptation to new systems is crucial. As the industry evolves, companies must evaluate their current processes. Investing in modern bag filling equipment may require time and resources, but the long-term benefits are undeniable.

Overview of Bag Filling Equipment Technologies in 2026

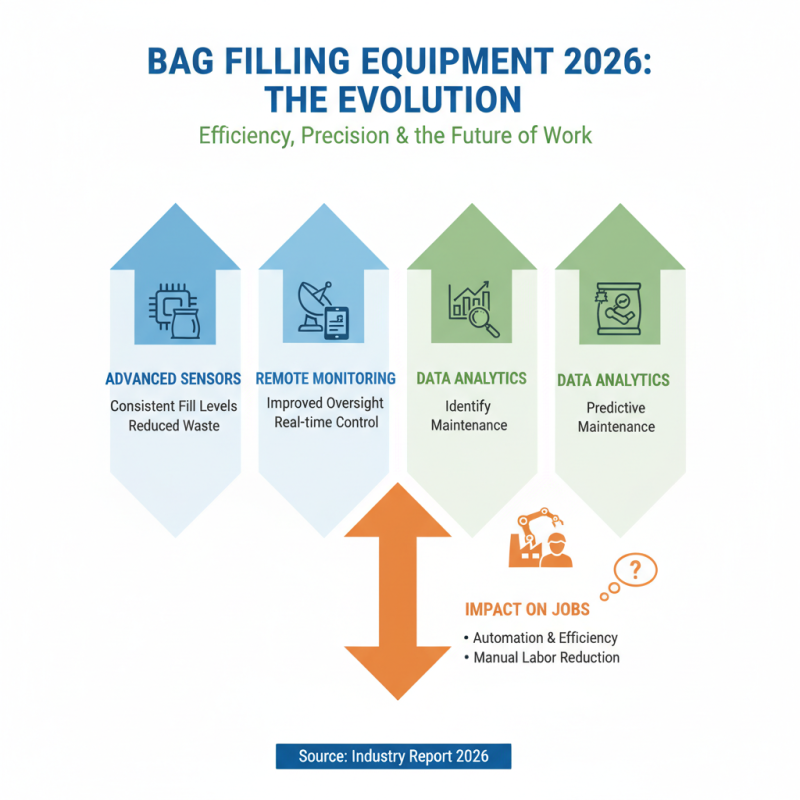

In 2026, bag filling equipment is evolving rapidly. New technologies are enhancing efficiency and precision. Many machines now use advanced sensors to ensure consistent fill levels. Operators can monitor these systems remotely, improving oversight. Real-time data analytics help identify bottlenecks quickly. However, reliance on technology raises questions about job displacement. Automation may reduce the need for manual labor.

Some equipment features innovative materials for construction. These materials enhance durability and sanitation. Maintenance is simplified, but costs may rise. Yet, not every facility can afford the latest machines. Small businesses might struggle to keep pace with advancements. This disparity creates a learning curve that some may find challenging.

Integration with existing systems remains a concern. Compatibility issues can lead to unexpected downtime. Staff training is essential but often overlooked. Skipping this step can lead to operational hiccups. Frequent updates to software can also complicate matters. Companies must strike a balance between innovation and practical functionality.

Key Features to Consider When Selecting Bag Filling Equipment

When selecting bag filling equipment, several key features are essential for operational efficiency. One critical aspect is filling speed. According to industry reports, filling rates of up to 20 bags per minute are often recommended for high-demand operations. This speed significantly reduces labor costs. However, some equipment may struggle to maintain this pace, leading to bottlenecks in production lines.

Another important consideration is the type of materials handled. Many facilities require versatile machines. These should effectively handle different materials, such as powders, granules, and liquids. Equipment that offers adjustable settings for various products can enhance flexibility. The ability to switch easily between different bag sizes is crucial, as fluctuating demands occur frequently. A notable report from the Packaging Machinery Manufacturers Institute (PMMI) highlighted that 30% of production delays stem from improper equipment adjustments.

Safety features also play a vital role in equipment selection. Machines should include fail-safes to prevent accidents. However, many operators overlook training protocols surrounding these safety features. This oversight can result in unreliable operation, which might compromise the entire system. Investing time in comprehensive training can mitigate this risk and ensure all team members understand the equipment's capabilities and limitations. Understanding the nuances of these features will lead to more informed decisions regarding bag filling equipment.

Exploring the Best Bag Filling Equipment of 2026 for Efficient Operations

This chart illustrates key features to consider when selecting bag filling equipment, including speed, accuracy, ease of use, versatility, and cost. Each feature is crucial for optimizing operations in a manufacturing environment.

Comparison of Leading Bag Filling Equipment Brands in 2026

In 2026, the landscape of bag filling equipment has undergone significant changes. Manufacturers are now focusing on efficiency and automation. Many models come with advanced features for precise filling. This not only enhances productivity but also reduces waste. Operators find that intuitive controls make handling easier. However, some machines still require frequent calibration.

When comparing leading brands, several factors stand out. The speed of operation is crucial. Some equipment fills bags quickly, but at the cost of accuracy. It’s a trade-off that not every operation can afford. Another aspect is versatility. Many machines can handle various bag sizes, enhancing their appeal. Yet, this comes with a learning curve that can be daunting for new users.

Maintenance remains a challenge for many users. Regular upkeep is necessary to ensure longevity. Unfortunately, some operators neglect this aspect. This leads to unexpected downtimes, which affect overall efficiency. Investing in training could alleviate some of these issues. Operators need to be aware of potential pitfalls in their choices. The perfect machine does not exist, and continuous evaluation is essential.

Case Studies: Successful Implementation of Bag Filling Solutions

Efficient bag filling solutions are critical for modern operations. In our exploration, several case studies reveal the impact of tailored approaches. One company had persistent issues with product spillage during the filling process. They implemented a new system featuring adjustable nozzles. This minor change significantly reduced waste and improved accuracy.

Another case study highlights a business that faced long downtime due to equipment malfunctions. After switching to a more robust design, they noticed a 30% increase in output. However, this transition wasn't seamless. Employees struggled to adapt to the new machinery, revealing the importance of training. Continuous improvement is essential, even with advanced technology.

A third example showcases a startup that invested in innovative filling equipment. They achieved remarkable consistency in filling weights. Still, their small team found it challenging to manage the equipment's complexities. Over time, they figured out the operational nuances. This learning process underscores a vital takeaway: even the best equipment requires human expertise and adaptability.

Future Trends in Bag Filling Equipment Automation and Efficiency

The evolution of bag filling equipment is vital for manufacturing and logistics. Automation continues to dominate trends. Advanced systems now incorporate artificial intelligence and machine learning. These innovations help streamline operations, reducing human error.

Efficiency is key. Modern equipment often features sensors and data analytics. This allows for real-time monitoring and adjustment. However, integrating these technologies presents challenges. Staff training is critical, yet often overlooked. New systems can intimidate employees, leading to resistance.

The aesthetic of equipment design is changing too. User-friendly interfaces are becoming the norm. This can enhance productivity but may also oversimplify complex tasks. Not every automated solution suits all operations. Each facility remains unique, requiring a tailored approach. Future developments will need to address these disparities for true efficiency.

Related Posts

-

Exploring the Future of Industrial Packaging: Trends and Innovations Driving Sustainability

-

2025 How to Optimize Your Packaging Automation for Maximum Efficiency

-

What is a Bag Filling Machine and How Does It Work?

-

Top 5 Automated Filling Machines for Efficient Production in 2023

-

2025 Complete Guide to Choosing the Best Bagging Equipment for Your Needs

-

How to Choose the Right Bagging Equipment for Your Needs?