NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

10 Best Industrial Containers for Efficient Storage Solutions

In an increasingly competitive market, businesses are continuously seeking efficient storage solutions to optimize their operations. Industrial containers play a pivotal role in this endeavor, providing versatile options for the safe and organized storage of materials. According to a recent report by Global Market Insights, the industrial container market is projected to reach $15 billion by 2030, driven by rising demand for bulk handling and storage solutions across various industries. This reflects the need for robust and innovative storage options that can improve operational efficiency.

As noted by industry expert Dr. Emily Carter, "The proper use of industrial containers not only enhances storage capabilities but also minimizes waste and boosts productivity." This sentiment underscores the growing recognition of industrial containers as essential tools in modern supply chain management. Whether it's for warehousing, manufacturing, or shipping, the right container can make a significant difference in how materials are handled and stored.

In this article, we will explore the 10 best industrial containers that not only meet safety and durability standards but also contribute to the optimization of storage solutions. As businesses look for ways to streamline their processes and reduce costs, understanding the benefits and applications of these containers is more important than ever.

Understanding the Importance of Industrial Containers in Storage

Industrial containers play a crucial role in optimizing storage solutions across various sectors. By understanding their importance, businesses can significantly enhance their operational efficiency and maximize available space. These containers are designed to withstand harsh conditions, provide durability, and ensure the safe storage of materials while maintaining a high level of organization. Their versatility makes them suitable for a range of applications, from storing raw materials in manufacturing to managing inventory in warehouses.

Moreover, industrial containers contribute to streamlined logistics and inventory management. With standardized sizes and shapes, they facilitate easier handling, transportation, and stacking, thereby reducing the risk of damage and loss. This organization leads to quicker retrieval times and better space utilization within facilities. In addition, the use of specialized containers can help in categorizing materials by their specific requirements, improving overall workflow and productivity. As industries continue to evolve, the significance of effective storage solutions through industrial containers remains paramount in achieving operational excellence.

10 Best Industrial Containers for Efficient Storage Solutions

| Container Type | Material | Capacity (Liters) | Dimensions (cm) | Stackable | Applications |

|---|---|---|---|---|---|

| Plastic Totes | Polypropylene | 60 | 60 x 40 x 30 | Yes | Warehouse, Retail |

| Metal Bins | Steel | 150 | 90 x 60 x 60 | Yes | Heavy Machinery Parts |

| IBC Totes | High-Density Polyethylene | 1000 | 120 x 100 x 115 | Yes | Chemical Storage, Liquid Transport |

| Drum Containers | Steel / Plastic | 200 | 58 x 90 (dia x height) | Yes | Food Industry, Chemicals |

| Stackable Crates | Polyethylene | 80 | 48 x 32 x 30 | Yes | Retail, Agriculture |

| Storage Bins | Polypropylene | 90 | 110 x 70 x 35 | Yes | Warehouse, Distribution |

| Heavy-Duty Trolley Container | Metal | 300 | 120 x 90 x 80 | Yes | Manufacturing, Warehousing |

| Folding Pallet Box | Plastic | 120 | 120 x 80 x 90 | Yes | Logistics, Shipping |

| Tool Chests | Steel | 75 | 60 x 30 x 40 | No | Workshops, Garages |

| Ventilated Bins | Plastic | 50 | 50 x 40 x 30 | Yes | Food Storage, Fresh Produce |

Types of Industrial Containers: A Comprehensive Overview

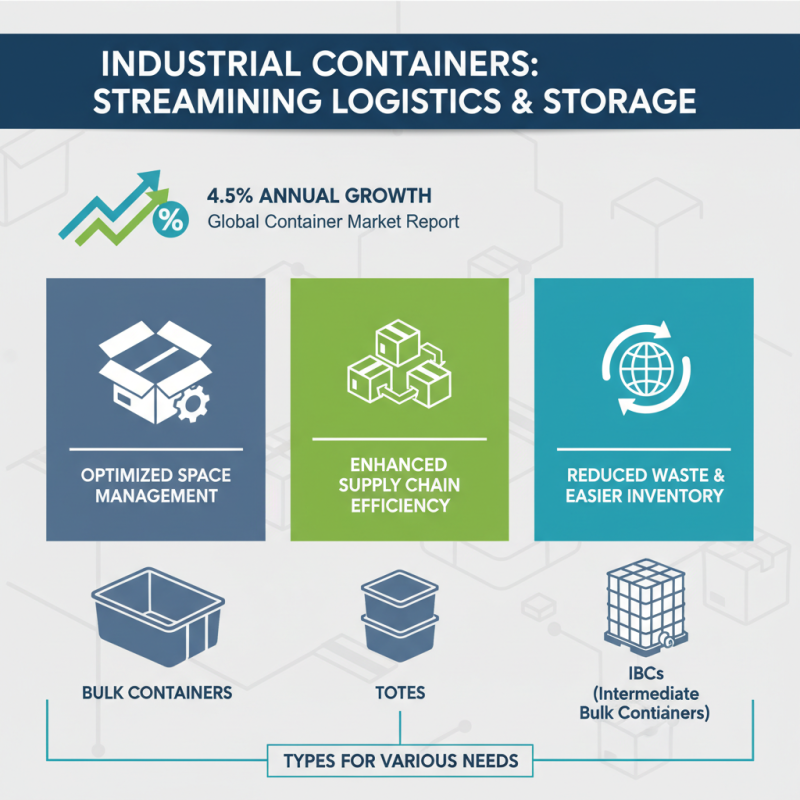

Industrial containers play a vital role in streamlining storage and logistics processes across various sectors. According to a report by the Global Container Market, the demand for industrial containers is expected to grow by 4.5% annually, driven by the need for efficient space management and enhanced supply chain operations. Various types of industrial containers cater to different storage needs, including bulk containers, totes, and IBCs (Intermediate Bulk Containers). Each type is designed to optimize space, reduce waste, and facilitate easier inventory management.

Bulk containers are ideal for storing large quantities of materials, ranging from raw materials to finished goods. A study from the Packaging Association highlights that the use of bulk containers can decrease shipping costs by up to 30%, as they allow for more effective utilization of cargo space. On the other hand, stackable containers and pallets are increasingly popular for their versatility and weight distribution benefits, which not only help in maximizing warehouse space but also in simplifying transportation logistics. Furthermore, with the rise of automation in warehouses, modular container designs have emerged, enabling seamless integration with automated retrieval systems, enhancing efficiency in industrial operations.

Key Features to Consider When Choosing Storage Containers

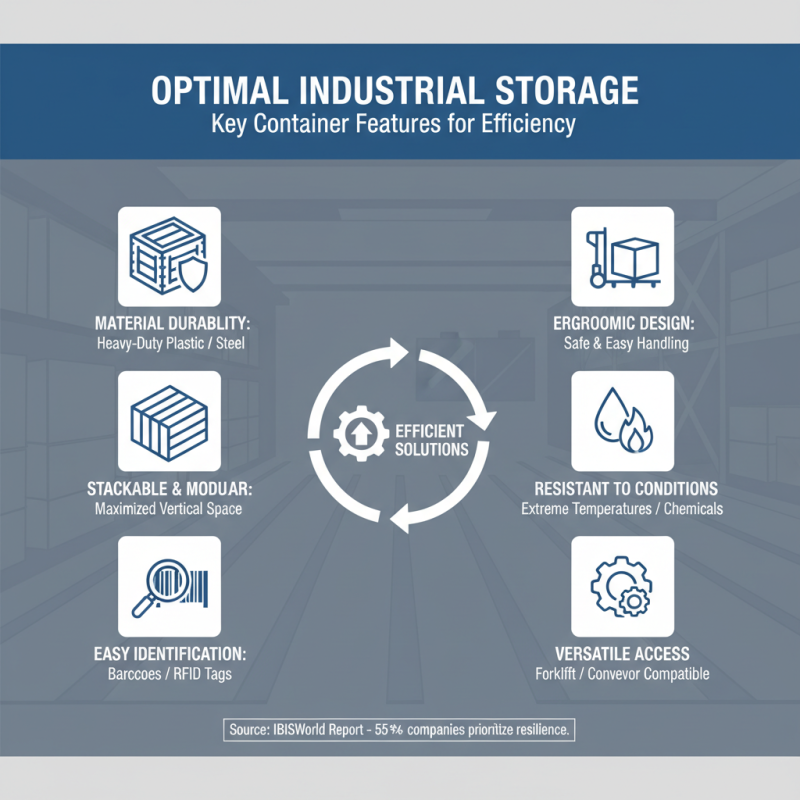

When it comes to selecting industrial containers for efficient storage solutions, several key features should be prioritized to maximize efficiency and organization. First and foremost is material durability; containers made from high-quality materials like heavy-duty plastic or steel are essential for longevity and structural integrity. According to a report by IBISWorld, over 55% of companies in the logistics sector emphasize the importance of container resilience to withstand constant handling and extreme conditions.

Another vital consideration is size and capacity. Choosing containers that accommodate varying volumes of materials can significantly enhance storage efficiency. Standardizing sizes across your storage system not only optimizes space but also facilitates easier stacking and transport. As highlighted in a recent study by Statista, companies that utilize standardized container sizes can improve their warehouse space utilization by up to 30%.

**Tip:** When assessing container sizes, consider the dimensions of your storage area and the nature of the items to be stored. Keep in mind the weight restrictions and ensure that the containers can be easily maneuvered with equipment like forklifts.

Additionally, compatibility with handling equipment is crucial. Containers should be designed for easy lifting and transport, allowing seamless integration with existing logistics systems. Many companies report that the right container design can reduce loading and unloading times by nearly 25%.

**Tip:** Test the containers in your operational environment before purchasing, ensuring they work well with your automated systems and are easy for your team to handle.

Top 10 Industrial Containers for Different Storage Needs

Choosing the right industrial container is crucial for optimizing storage in various environments, whether for manufacturing, warehousing, or shipping. Different storage needs entail specific requirements, such as size, durability, and ease of access. For example, stacking containers are ideal for maximizing vertical space, while modular containers can be adjusted according to changes in inventory.

When selecting an industrial container, consider the material and design that will best suit your operation. For heavy-duty applications, options made from reinforced steel or high-density polyethylene provide superior strength and longevity. Additionally, containers with features like ergonomic handles or integrated wheels enhance mobility, making it easier to transport goods around your facility.

Tips for selecting industrial containers include assessing the specific weight capacity you require, as overloading a container can lead to safety hazards. Also, consider the environmental conditions—such as exposure to chemicals or extreme temperatures—that your containers will face. Finally, think about future scalability; choosing modular or expandable containers can save time and resources as your storage needs change over time.

Best Practices for Organizing and Maintaining Industrial Containers

When it comes to organizing industrial containers for efficient storage, best practices are essential to maximizing space and ensuring easy access to materials. One of the fundamental techniques is categorizing containers based on the type of contents they hold. Utilizing color-coding or labeling systems can significantly enhance organization, enabling quick identification and retrieval. Additionally, implementing a bin rotation system ensures that older stock is used before newer arrivals, which minimizes waste and maintains an efficient inventory flow.

Maintaining containers is equally critical for effective storage solutions. Regular inspections for wear and tear can help prevent container failures that might disrupt operations. Cleaning containers routinely not only extends their lifespan but also ensures that stored materials remain uncontaminated. Furthermore, developing a standardized maintenance schedule can streamline this process, allowing for proactive measures rather than reactive fixes. By adhering to these organizational and maintenance practices, industries can foster a more productive work environment that enhances operational effectiveness.

Storage Efficiency of Different Industrial Containers

This chart illustrates the efficiency ratings of various types of industrial containers commonly used for storage solutions. Each container type is ranked on a scale of 1 to 10 based on its effectiveness in organization and maintenance in an industrial environment.

Related Posts

-

The Future of Packaging Machines Innovations Transforming the Industry

-

How to Choose the Right Filling Machines for Your Packaging Needs

-

Best Automated Bagging Systems for Efficient Packaging Solutions

-

Maximizing Efficiency: The Future of Bagging Equipment in the Food and Beverage Industry

-

Understanding the Future of Industrial Packaging Innovations and Sustainability Trends

-

Exploring the Future of Industrial Packaging: Trends and Innovations Driving Sustainability