NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

How to Choose the Right Filling Equipment for Your Production Needs

Choosing the right filling equipment for your production needs is a critical decision that can significantly impact the efficiency and quality of your manufacturing process. According to Richard Thompson, a leading expert in the filling equipment industry, "The right filling equipment not only enhances productivity but also ensures that product integrity is maintained throughout the packaging process." This insight highlights the importance of selecting equipment that aligns with both the technical specifications of your product and the operational demands of your production line.

In today's marketplace, manufacturers face unique challenges that require careful consideration and strategic planning when it comes to filling equipment. With a plethora of options available—ranging from manual fillers to highly automated systems—it is essential to evaluate not only the initial costs but also the long-term benefits, including maintenance, scalability, and adaptability to changing production requirements. Making an informed choice allows for optimized operations, improved product consistency, and ultimately, greater customer satisfaction. As production needs evolve, understanding the nuances of filling equipment selection becomes increasingly vital for businesses aiming to stay competitive.

Factors to Consider When Selecting Filling Equipment for Production

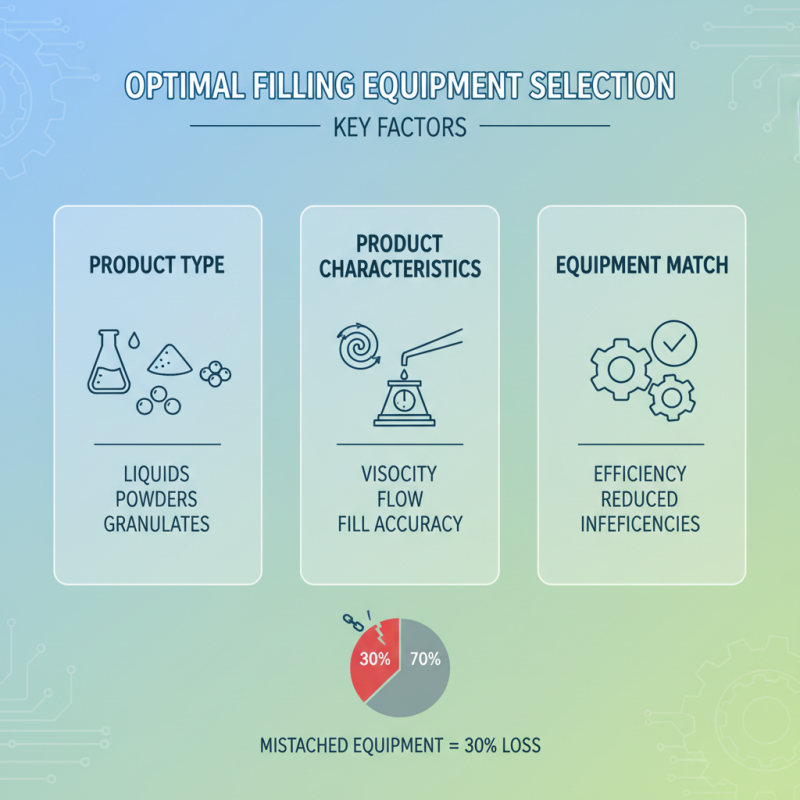

When selecting filling equipment for production, several critical factors must be considered to ensure efficiency and effectiveness. First, the type of product being filled plays a significant role. Liquids, powders, and granulated products each have unique filling requirements and behaviors. According to a report by the International Packaging Association, approximately 30% of production inefficiencies stem from mismatched filling equipment and products. Understanding the viscosity, flow characteristics, and required fill accuracy is vital for choosing the correct machinery.

Another essential factor is production volume. Companies must assess their daily output to determine the sizing and speed of the filling equipment. For instance, equipment designed for small batches may not handle high-volume production effectively, potentially leading to bottlenecks. A study published in the Journal of Manufacturing Science highlights that investing in the right equipment can increase production rates by up to 25%, significantly impacting overall operational efficiency.

Tips: Always consider future growth when selecting filling equipment. Opt for machines that offer scalability or modularity to accommodate changes in production volume or product lines without needing replacement. Furthermore, ensure that the selected equipment complies with industry standards and regulations to guarantee safety and reliability. Engaging with suppliers for custom solutions can also optimize the filling process for specific production needs.

Types of Filling Equipment: Advantages and Disadvantages in Different Industries

When it comes to filling equipment, various types cater to the unique needs of different industries. For instance, liquid filling machines can be gravity-fed or pressure-based, offering distinct advantages and disadvantages. Gravity fillers are often simpler and more cost-effective, making them ideal for less viscous liquids. Conversely, pressure fillers are more suitable for thicker liquids or products that require a higher filling speed, though they can be more complex and expensive to maintain.

In the realm of solids and powders, volumetric fillers provide precise measurements and are widely used in food, pharmaceutical, and chemical sectors. These machines ensure consistent fill volumes, enhancing product quality and reducing waste. However, they can struggle with variations in the density of the product, requiring frequent adjustments to maintain accuracy. Alternatively, auger fillers can handle a wider range of product consistency, but often come with a steeper learning curve in operation and setup, particularly for newcomers to the industry. Each type of filling equipment has its specific use cases, making it critical for manufacturers to thoroughly assess their production needs before making a decision.

How to Choose the Right Filling Equipment for Your Production Needs

| Filling Equipment Type | Advantages | Disadvantages | Ideal Industries |

|---|---|---|---|

| Piston Fillers | High accuracy, suitable for viscous products | Slower fill rates, can be more expensive | Food, cosmetics, pharmaceuticals |

| Gravity Fillers | Simple operation, cost-effective | Less accurate for thick liquids, not suitable for foamy products | Beverages, oils, and some cleaner products |

| Vacuum Fillers | Reduces air bubbles, ideal for foamy products | More complex, higher maintenance | Food industry, sauces, and liquid detergents |

| Aseptic Fillers | Suitable for shelf-stable products, prolongs shelf life | High initial investment, complex operation | Dairy, juices, and pharmaceuticals |

| Counter Pressure Fillers | Maintains carbonation in beverages | Requires special equipment, more costly | Carbonated drinks, beer, sparkling wines |

Impact of Production Volume on Filling Equipment Selection Process

When selecting the right filling equipment for production, understanding the impact of production volume is crucial. Production volume dictates not only the type of filling equipment needed but also its configuration and efficiency. For low-volume production runs, semi-automatic filling machines may suffice, allowing for flexibility and ease of use. These machines often facilitate quick changeovers and can be easily adapted to different product types, making them ideal for smaller businesses or those testing new products.

In contrast, high-volume production demands more sophisticated machinery that can maintain consistency and speed. Automated filling systems become essential in these scenarios, as they can handle larger quantities while reducing the risk of human error. Such systems often incorporate advanced technologies, including sensors and programmable logic controls, ensuring precise filling accuracy and minimizing downtime. Additionally, the selection process should consider factors like the product's viscosity, container size, and required throughput, which all play a role in optimizing the performance of the filling equipment. Thus, aligning production volume with the right filling technology is key to maximizing operational efficiency and meeting market demands effectively.

How to Choose the Right Filling Equipment for Your Production Needs

Key Features to Evaluate in Quality Filling Equipment Models

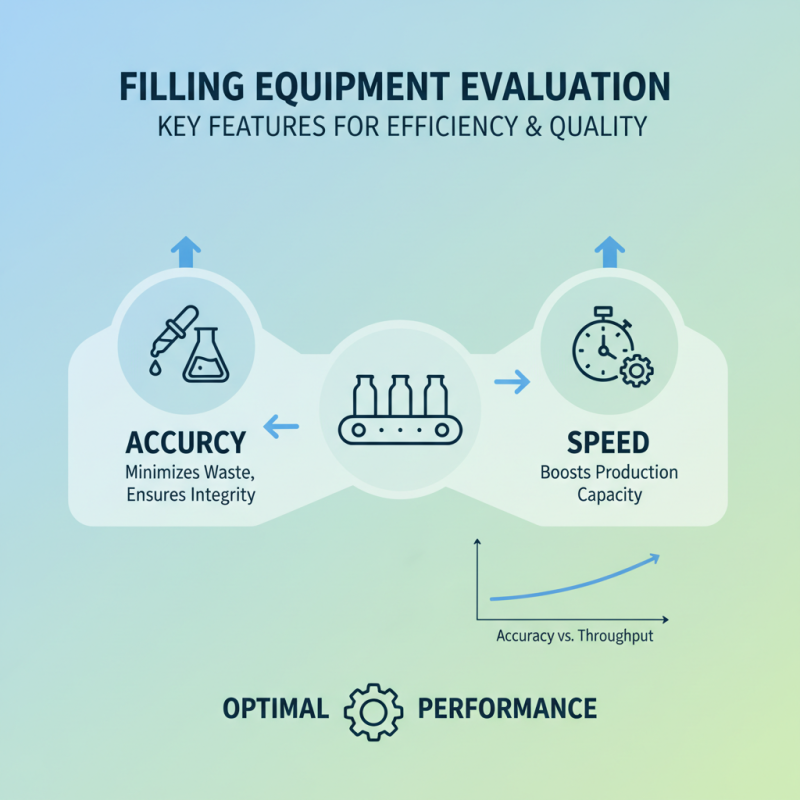

When evaluating filling equipment for your production needs, it's essential to focus on key features that directly impact efficiency and product quality. Firstly, consider the filling accuracy and speed of the equipment. High precision is crucial in ensuring that each container is filled to the correct volume, minimizing waste and maintaining product integrity. Additionally, the speed of the filling process can significantly affect your overall production capacity, so look for models that strike a balance between accuracy and throughput.

Another important feature to assess is the versatility of the filling equipment. Depending on your product line, you may need a machine that can handle various container types and sizes, from small bottles to larger barrels. The ability to easily adjust settings or switch between different filling applications can enhance flexibility and reduce downtime. Lastly, pay attention to the ease of maintenance and cleaning. Equipment designed for straightforward maintenance will help ensure consistent operation and reduce the likelihood of breakdowns, which can disrupt production schedules. By focusing on these key characteristics, you can select filling equipment that aligns perfectly with your operational requirements.

Cost Analysis: Budgeting for Filling Equipment in Your Production Line

When considering the acquisition of filling equipment, a thorough cost analysis is essential to ensure that budget allocations align with production goals. Recent industry reports indicate that filling equipment can represent up to 15-25% of a production line’s overall budget. This significant expenditure underscores the importance of understanding the long-term implications of your choices, including maintenance costs, production speed, and versatility of the equipment. For instance, selecting a semi-automatic filling machine may cost less upfront but could lead to higher labor costs and lower throughput in the long run compared to a fully automated system.

Moreover, it's essential to evaluate the total cost of ownership (TCO) when budgeting for filling equipment. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), the TCO can encompass installation, training, maintenance, and downtime costs. A well-chosen filling machine can result in cost savings through increased efficiency, reducing product waste, and minimizing operational disruptions. Therefore, when budgeting, consider not only the initial investment but also how the machine's efficiency will translate into cost savings over time, ultimately impacting your bottom line.

Related Posts

-

10 Essential Tips for Choosing the Right Packaging Machines: Maximize Efficiency and Reduce Waste

-

2025 How to Optimize Your Packaging Automation for Maximum Efficiency

-

How to Choose the Right Filling Machines for Your Packaging Needs

-

How to Choose the Right Industrial Packaging Equipment for Your Business Needs

-

2025 Top Industrial Packaging Machines Trends and Innovations You Should Know

-

Best Automated Bagging Systems for Efficient Packaging Solutions