NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

How to Choose the Right Filling Machines for Your Packaging Needs

Choosing the right filling machines for your packaging needs is a crucial decision for any business involved in production and distribution. As the industry evolves, the demand for efficient, versatile, and reliable filling solutions has never been higher. According to John Smith, an expert in the field of packaging technology, "The right filling machine can significantly enhance productivity and reduce operational costs." With a vast array of options available on the market, understanding the specific requirements of your product and production process is essential for selecting the most suitable equipment.

In this dynamic landscape, businesses must consider various factors when evaluating filling machines, including the type of product, packaging format, and desired speed of operation. Customized solutions are often necessary, as the effectiveness of a filling machine can greatly influence the overall efficiency of a packaging line. Thus, thorough research and expert insight play a pivotal role in ensuring that organizations can adapt to market demands while maintaining quality standards and maximizing output. As the right filling machine can set the foundation for a successful packaging operation, it is not just a piece of machinery but a strategic asset in a company's growth trajectory.

Understanding Your Packaging Requirements

Understanding your packaging requirements is a crucial first step when selecting the right filling machines. Packaging needs can vary significantly based on the type of product, its viscosity, and the desired shelf life. For instance, liquid products like sauces or beverages may necessitate specific filling machines that can handle varying viscosities while ensuring accuracy and minimal spillage. Conversely, for dry products such as powders or granules, a different kind of filling technology, like auger fillers, may be more suitable. Assessing the nature of the products you are packaging will help narrow down the options effectively.

Another essential consideration involves the packaging format. Understanding whether you need pouches, bottles, jars, or cartons will dictate the kind of filling machine required. Each format has its unique demands regarding speed, precision, and compatibility with closure systems. Additionally, operational throughput—how quickly products need to be filled and packaged—can influence machine selection as well. It is also wise to consider scalability; the chosen machine should not only meet current capacity needs but also adapt to future growth and changing requirements in packaging. Analyzing these parameters will ensure you select a filling machine that optimally supports your packaging processes.

Types of Filling Machines Available in the Market

When selecting the appropriate filling machines for your packaging needs, it's crucial to understand the various types available in the market. The primary categories include volumetric, gravimetric, and time-based machines. Volumetric fillers measure the exact volume of liquid or product to be dispensed, ensuring consistent fill levels, making them ideal for liquids like juices or sauces. These machines are renowned for their speed and accuracy, catering to high-volume production environments.

Gravimetric filling machines, on the other hand, utilize weight measurement to determine the amount of product dispensed. This type often proves advantageous for dry powders or granulated products, as it can account for variations in product density effectively. Gravimetric systems are particularly beneficial when precise weights are necessary, helping to minimize product waste and maintain quality control.

Lastly, time-based filling machines operate by controlling the duration of the filling cycle, suitable for thin liquids where consistency is less critical. While they can be more cost-effective and simpler to operate, they might not offer the precision needed for thicker or more variable products. By understanding these types of filling machines, businesses can make informed choices that align with their packaging requirements and production goals.

How to Choose the Right Filling Machines for Your Packaging Needs

| Filling Machine Type | Best For | Filling Volume | Speed (bottles per minute) | Typical Applications |

|---|---|---|---|---|

| Volumetric Filling Machine | Liquids & Viscous Products | 50ml - 5L | 20 - 100 | Beverages, Sauces |

| Piston Filling Machine | Thick Liquids & Pastes | 50ml - 10L | 10 - 60 | Cosmetics, Pharmaceuticals |

| Gravity Filling Machine | Thin Liquids | 100ml - 5L | 10 - 50 | Wine, Oil |

| Auger Filling Machine | Powders & Granules | 50g - 5kg | 20 - 80 | Coffee, Detergents |

| Cup Filling Machine | Ready-to-eat Foods | 100g - 1kg | 30 - 100 | Yogurt, Soups |

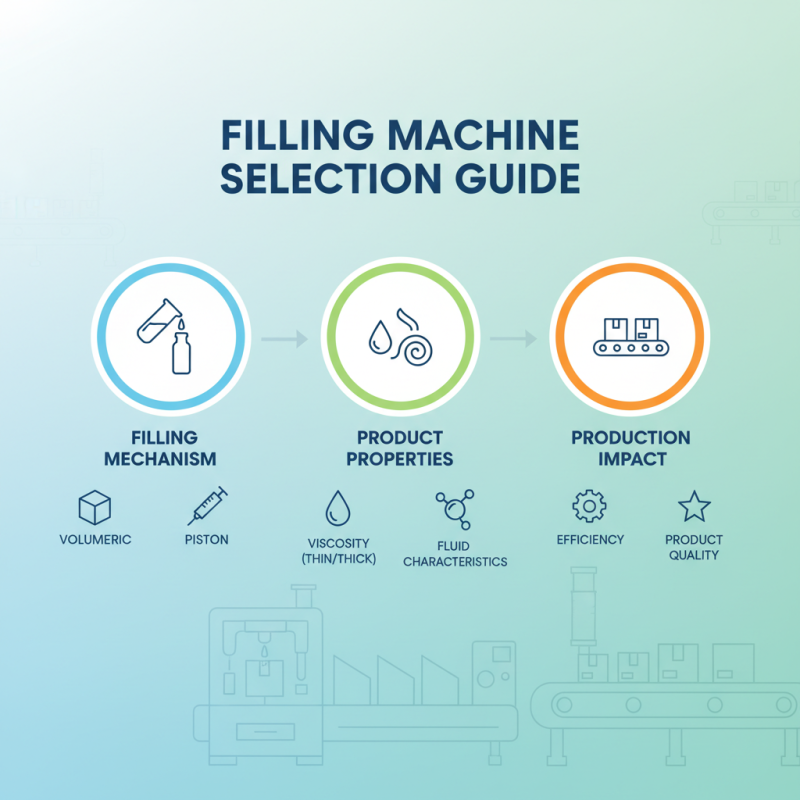

Key Features to Consider When Selecting Filling Machines

When selecting filling machines for your packaging needs, it is crucial to focus on several key features that can significantly impact your production efficiency and product quality. One of the primary considerations is the type of filling mechanism that aligns best with your product. This could include volumetric, gravimetric, or piston filling, each suited for different fluid characteristics. Understanding the viscosity and properties of the liquid or paste being filled will help determine the most effective filling method.

Another important feature to consider is the machine's speed and capacity. Depending on your production volume, you may require a high-speed filling machine that can handle large quantities in a short timeframe. Additionally, pay attention to the machine's flexibility in terms of handling various container sizes and shapes. Adjustability can save time and costs when switching between different products. Lastly, think about the automation level you desire—fully automated machines can enhance efficiency but may require a higher upfront investment, while semi-automated options may be a better fit for smaller operations.

Evaluating Supplier Capabilities and Support Services

When selecting filling machines for packaging, evaluating supplier capabilities and support services is essential to ensure the longevity and efficiency of your production line. According to a report by Grand View Research, the global filling machine market is projected to reach USD 6.5 billion by 2025, highlighting the importance of reliable suppliers in a competitive industry. One crucial aspect of supplier evaluation is the technical support offered. A robust support system can greatly reduce downtime during production, ensuring that any machine malfunctions are addressed quickly.

Furthermore, it's vital to assess the technological competencies of your suppliers. Factors such as automation integration and equipment adaptability are key to achieving optimal performance. Industry insights suggest that companies investing in smart technologies, such as IoT and AI in filling operations, can experience efficiency gains of up to 30%. Thus, partnering with suppliers who demonstrate a commitment to innovation and provide ongoing technical training for your staff can significantly enhance your packaging processes.

Prioritizing these criteria will not only meet immediate production needs but also position your business for future growth in a rapidly evolving market.

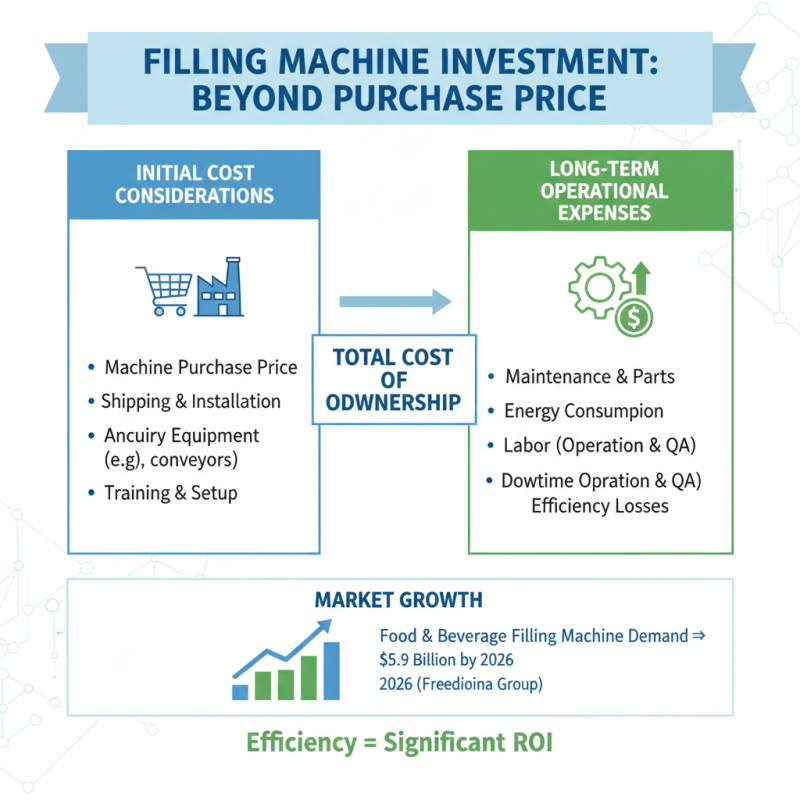

Budgeting for Your Filling Machine Investment

When budgeting for a filling machine investment, it is essential to understand not only the initial purchase cost but also the long-term operational expenses associated with the equipment. According to a report by Freedonia Group, the demand for filling machines in the food and beverage sector is expected to reach $5.9 billion by 2026, reflecting the industry's consistent growth. This indicates that a careful consideration of filling machine options can lead to significant returns as operational efficiency improves.

In addition to the purchase price, businesses should account for maintenance, repair, and potential upgrades needed to keep the equipment operational. Studies show that maintenance can cost up to 5-15% of the initial investment annually. Companies may also want to consider the cost of consumables, such as components that may need regular replacement or the impact of energy consumption on overall operating costs. As reported by PMMI, the Association for Packaging and Processing Technologies, an efficient filling machine can reduce labor costs by up to 30% and energy costs by approximately 20%, making it crucial to select a machine that not only fits the budget but also enhances productivity and reduces total cost of ownership over its lifespan.

Related Posts

-

The Future of Filling Machines in Sustainable Packaging Innovations

-

Top 5 Automated Filling Machines for Efficient Production in 2023

-

The Future of Packaging Machines Innovations Transforming the Industry

-

2025 Complete Guide to Choosing the Best Bagging Equipment for Your Needs

-

2025 How to Optimize Your Packaging Automation for Maximum Efficiency

-

Maximizing Efficiency: The Future of Bagging Equipment in the Food and Beverage Industry