NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

How to Implement Packaging Automation for Your Business?

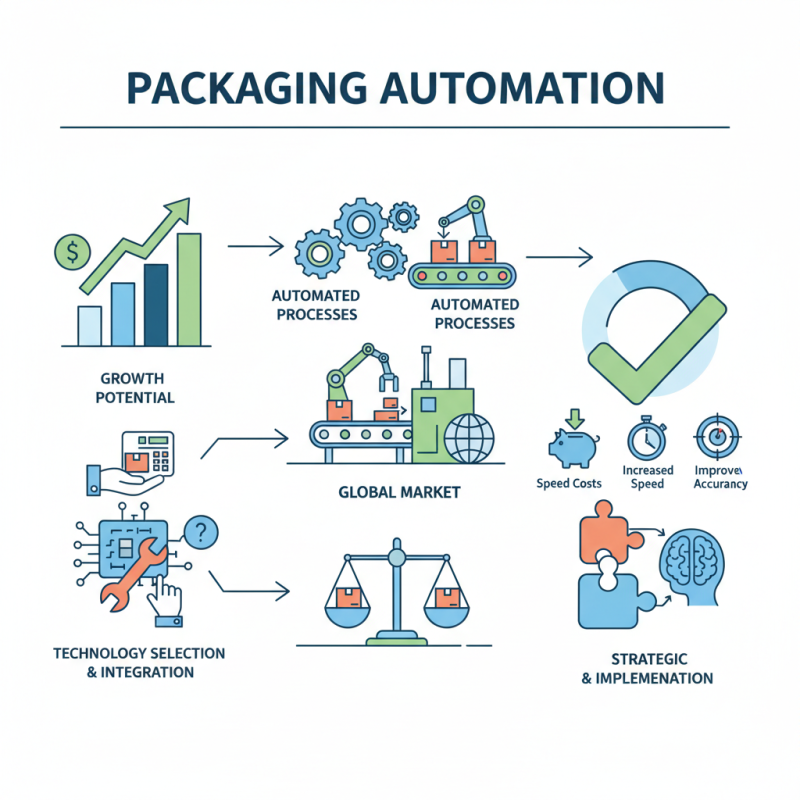

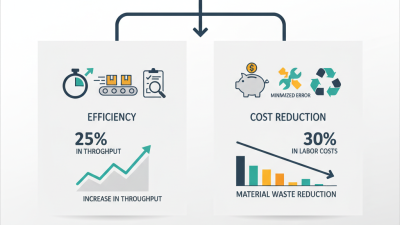

In today's competitive market, packaging automation is essential for efficiency. According to a report by Smithers Pira, the global packaging automation market is expected to reach $65 billion by 2025. This indicates a significant growth potential for businesses that adopt such technologies. Implementing packaging automation can streamline processes, reduce labor costs, and improve accuracy.

However, businesses may face challenges during this transition. Many companies struggle with selecting the right technologies that fit their specific needs. A 2022 survey showed that nearly 40% of manufacturers find it difficult to integrate automated solutions. This situation highlights the importance of thoughtful planning. Automation isn't just about replacing manual labor; it's about creating a seamless workflow.

Investing in packaging automation can yield substantial benefits. Nevertheless, organizations must assess their current operations closely. The risk of over-automation can lead to issues like production delays and increased costs. Finding the balance between automation and manual processes is crucial for success. Taking the plunge into packaging automation requires careful consideration and strategic implementation to truly harness its potential.

Understanding the Importance of Packaging Automation in Business

In today’s competitive market, packaging automation is crucial for businesses. It enhances efficiency and reduces costs. Many companies struggle to keep up with demand. Manual packaging processes can lead to errors, delays, and wasted resources. Embracing automation simplifies these tasks. It streamlines workflows and increases productivity.

Consider these tips before implementation. Start small. Test the automation within one part of your process. This allows you to identify any potential issues without overwhelming your operations. Next, train your employees. They need to adapt to new technologies. Involving your team early can ease transitions.

Monitor the results closely. Automation may not always yield immediate benefits. There might be setbacks. It’s important to gather feedback and adjust your approach accordingly. This reflection helps refine the system for better outcomes. Ultimately, integrating automation can propel your business forward, but it requires careful planning and execution.

Assessing Your Current Packaging Process for Automation Opportunities

Assessing your current packaging process is crucial for identifying automation opportunities. Start by observing the entire workflow. Look at each step, from packing to shipping. Are there delays? Repetitive tasks? Engage your team in this evaluation. They often know what slows things down.

**Tips:** Use flowcharts to visualize the process. Highlight bottlenecks. This can reveal steps that might benefit from automation.

Next, gather data on packaging times. Document how long tasks take. Recognize patterns; are certain products consistently slower to pack? This information is invaluable. Automating those specific tasks might speed everything up. Sometimes, the simplest tasks can yield the biggest benefits.

**Tips:** Consider feedback loops. Regularly review automation successes and failures. Adjust your approach based on what you learn. Continuous reflection can drive better results.

Packaging Automation Opportunities Assessment

Choosing the Right Packaging Automation Solutions and Equipment

Choosing the right packaging automation solutions and equipment is crucial for any business looking to enhance efficiency. Start by assessing your packaging needs. What types of products do you handle? Consider their sizes, shapes, and materials. Each product may require a different approach. For instance, small products might need specific labeling and sealing equipment. Larger items can demand heavy-duty packing machines.

Evaluate the technology available in the market. Look for equipment that offers flexibility and can adapt as your product line changes. Automated systems with user-friendly interfaces are often more efficient. Keep an eye on maintenance needs; complex machinery can lead to downtime. It's important to find a balance between advanced technology and practicality.

Investing in automation isn't just about speed. Quality must not be sacrificed for efficiency. During your research, identify potential pitfalls. Sometimes, businesses rush into purchasing new systems without fully understanding their operational impact. This can lead to misalignment with supply chain processes. Be aware of these challenges as you make your choice.

Implementing Packaging Automation: A Step-by-Step Guide

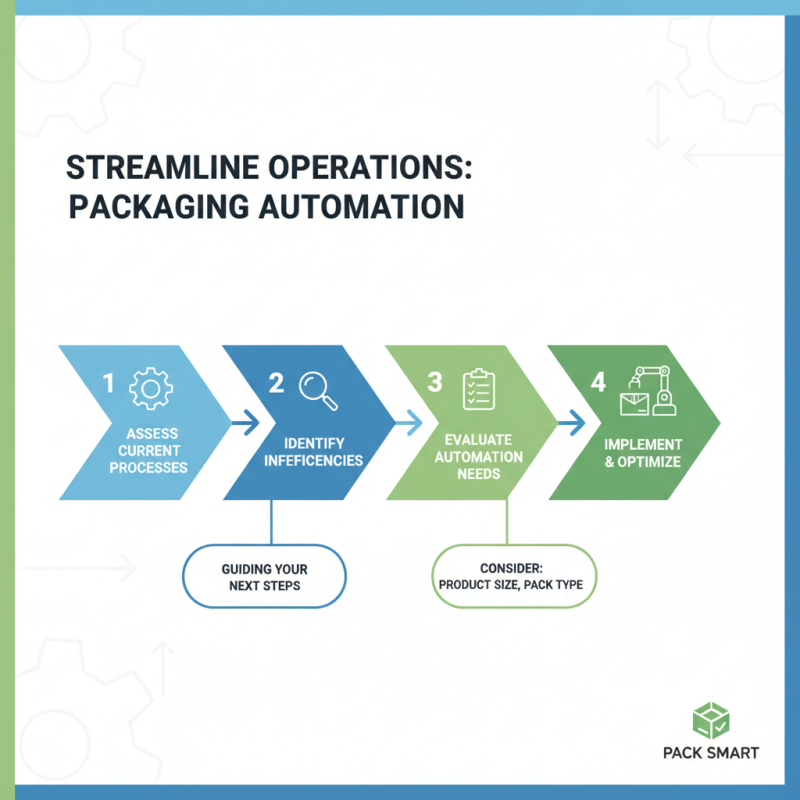

Implementing packaging automation can streamline your operations. Start by assessing your current processes. Identify inefficiencies. This will guide your next steps. Evaluate what kind of automation suits your needs. Consider factors like product size and packaging type.

Tips: Focus on user training. Investing in your team enhances efficiency. Provide hands-on experience with new machines. It’s crucial for smooth operation. Monitor the implementation closely. Gather feedback from your staff. This ensures everyone adapts to the changes.

Don’t expect a perfect transition. Challenges will arise. You may face resistance from employees. Be open to their concerns. Adjust your approach based on their feedback. This will build trust and improve outcomes. Lastly, consistently measure the performance of new systems. Aim for continuous improvement rather than instant perfection.

Training Employees and Ensuring Smooth Transition to Automated Systems

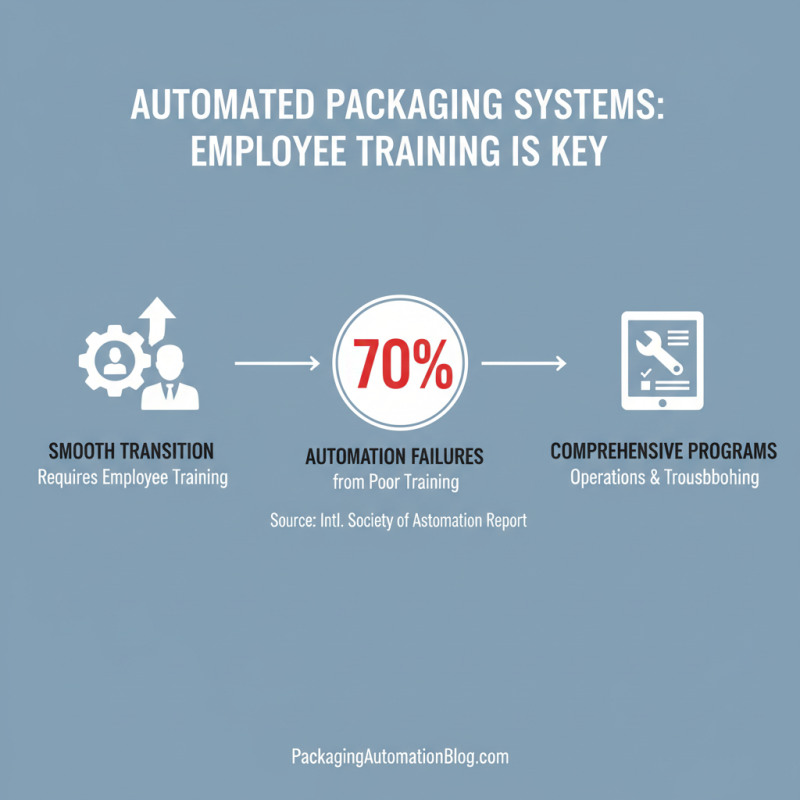

Transitioning to automated packaging systems involves careful training for employees. According to a report by the International Society of Automation, 70% of automation failures stem from poor employee training. This statistic highlights the need for comprehensive training programs. Employees must understand how to operate new machinery and troubleshoot common issues.

Hands-on training sessions are essential. Simulations can help staff practice without impacting production. Regular feedback loops also promote improvement. Employee surveys can reveal areas needing more focus. Additionally, creating a mentorship program could pair experienced workers with newcomers. This fosters a culture of learning and support.

Transitioning to automation may come with resistance. Some employees may fear job loss or feel overwhelmed. Open communication can address these concerns. Informing teams about the benefits of automation, such as increased efficiency and reduced repetitive tasks, may ease fears. Partners and suppliers should also be involved in the transition process for seamless integration. Proper training will lead to smooth operations and a more confident workforce.

Related Posts

-

Revolutionizing E-commerce: How Automated Packaging Enhances Delivery Efficiency and Customer Satisfaction

-

10 Essential Tips for Choosing the Right Packaging Machines: Maximize Efficiency and Reduce Waste

-

2025 How to Optimize Your Packaging Automation for Maximum Efficiency

-

Why Industrial Packaging Machines Are Essential for Modern Manufacturing Success

-

How to Choose the Right Automated Packaging Solutions for Your Business

-

Benefits of Automated Packaging for Efficiency and Cost Reduction