NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

What is Industrial Packaging Equipment and Its Importance in Manufacturing

Industrial packaging equipment plays a critical role in manufacturing. It ensures products are protected during transportation and storage. According to a report by MarketsandMarkets, the global industrial packaging market is projected to reach $750 billion by 2025, reflecting a robust growth trend. Efficiency in this sector is crucial for businesses aiming to reduce costs and increase sustainability.

An expert in the field, Dr. Emily Turner, states, “Effective industrial packaging equipment not only safeguards products but also enhances supply chain efficiency.” Many manufacturers struggle with selecting the right equipment. This can lead to wasted resources and damaged goods. Packaging choices directly impact a company's bottom line.

While advancements are beneficial, there remain challenges. Companies must navigate complex machinery options. Additionally, balancing cost and quality is often difficult. Finding the right solution is not straightforward. Industrial packaging equipment decisions require careful consideration. It's a vital investment for successful manufacturing operations.

Definition of Industrial Packaging Equipment

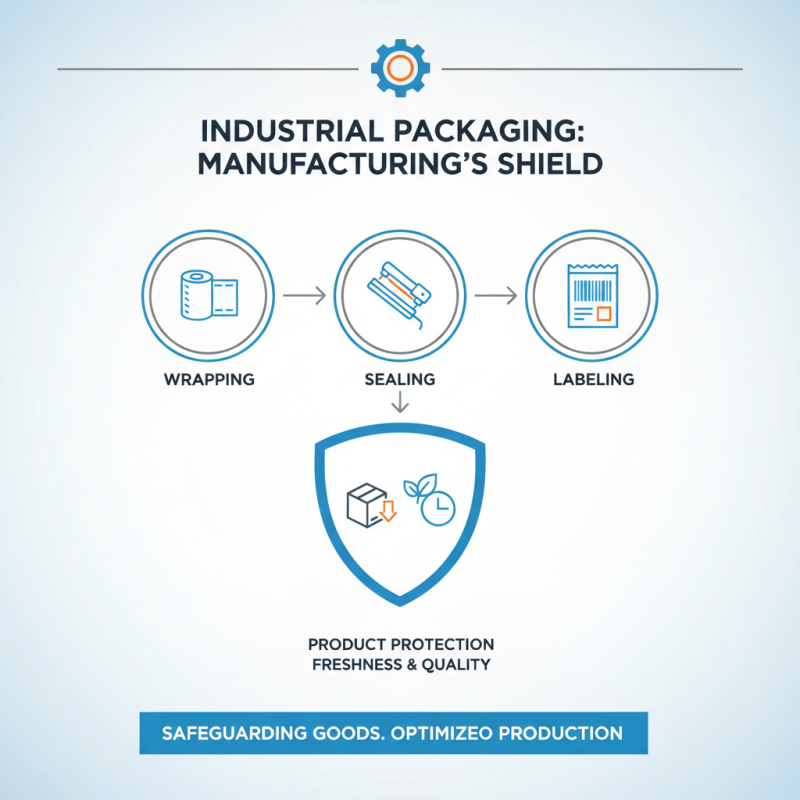

Industrial packaging equipment plays a crucial role in the manufacturing sector. This equipment is designed to package products efficiently, ensuring they are ready for distribution. It includes machines for sealing, labeling, and stacking. Each piece of equipment serves a specific purpose in the packaging process.

The significance of industrial packaging equipment goes beyond just containment. Proper packaging protects products from damage during transport. It can also enhance shelf life, ensuring items remain fresh. However, manufacturers often overlook this aspect. The wrong choice of equipment can lead to inefficiencies and increased costs. Regular evaluations are essential to avoid these pitfalls.

In addition, the impact of packaging on waste management is substantial. Using the right materials can reduce environmental footprints. Yet, many businesses still struggle with this. Balancing costs and sustainability is a challenge, but it’s critical for future success. Investing in quality equipment is vital. Each decision in packaging can have long-term effects on both the product and the environment.

Types of Industrial Packaging Equipment Used in Manufacturing

Industrial packaging equipment plays a crucial role in manufacturing. Different types of equipment help streamline processes. For example, automatic strapping machines secure packages efficiently. These machines save time and reduce labor costs. They are often used for heavy or bulk items.

Another important type is the stretch wrapping machine. This equipment utilizes elastic film to secure products on pallets. It enhances stability during transportation. A shrink wrap machine also serves a similar purpose. It envelops items with plastic to preserve freshness and protection.

However, companies sometimes overlook maintenance. Neglected machines can slow down production. Regular checks are vital for optimal performance. Efficiency can be lost when machines malfunction. Investing in quality equipment is essential, but so is ongoing care. The balance of investment and maintenance can define success in manufacturing.

What is Industrial Packaging Equipment and Its Importance in Manufacturing

| Type of Equipment | Function | Key Benefits | Common Uses |

|---|---|---|---|

| Automatic Stretch Wrappers | Wrap products with stretch film | Enhances load stability, reduces material waste | Palletized loads, logistics operations |

| Carton Sealing Machines | Seal boxes with tape | Increases productivity, provides secure closures | E-commerce packaging, retail goods |

| Filling Machines | Fill containers with liquid or powder | Ensures accurate dosing, minimizes waste | Food and beverage, pharmaceuticals |

| Labeling Machines | Apply labels to products or packages | Enhances brand visibility, regulatory compliance | Beverages, consumer goods |

| Shrink Wrapping Machines | Shrink wrap products with heat | Provides bundle protection, improves presentation | Food items, electronics |

Role of Industrial Packaging in Supply Chain Efficiency

Industrial packaging plays a critical role in supply chain efficiency. It serves as a protective barrier, ensuring products reach their destinations safely. Effective packaging minimizes damage during transit, reducing costs and waste. Additionally, it facilitates easier handling and storage. Properly designed packages can fit more products, optimizing space utilization.

Moreover, packaging influences the speed of the supply chain. When packaged correctly, items can be loaded and unloaded quickly. This reduces delays and maintains a steady flow of goods. However, not all packaging is created equal. Inadequate packaging can lead to inventory losses. Occasionally, businesses overlook the importance of testing their packaging solutions. It’s essential to rethink and adapt based on material quality and design.

Communication is another aspect affected by packaging. Clear labeling and instructions streamline the distribution process. Yet, many companies miss this opportunity. They may prioritize aesthetics over functionality. The balance between appearance and utility requires careful consideration. Ultimately, efficient industrial packaging can enhance overall supply chain performance.

Benefits of Using Industrial Packaging Equipment in Production

Industrial packaging equipment plays a crucial role in the manufacturing process. Many manufacturers rely on these tools to ensure their products are safely packaged and protected. This equipment includes machines for wrapping, sealing, and labeling. Each of these functions is essential to maintaining product integrity. Proper packaging prevents damage during transport. It also helps preserve the freshness of goods.

Using industrial packaging equipment can enhance efficiency. Automated systems reduce the time needed for wrapping and packing. Workers can focus on other tasks. However, it’s not always perfect. Some machines might malfunction, leading to delays. Operators need training to minimize errors. Getting the right equipment is vital, but the choice can be overwhelming. Compatibility with existing processes must be considered carefully.

Moreover, investment in packaging technology can lead to significant cost savings. Well-packaged products reduce waste and returns. This, in turn, boosts overall profitability. However, manufacturers must also reflect on their needs. What might work for one facility may not suit another. Constant evaluation and adaptation of packaging methods can drive better results in the long run.

Future Trends in Industrial Packaging for Sustainable Manufacturing

As industries strive for sustainability, industrial packaging is evolving. This shift focuses on reducing waste and utilizing eco-friendly materials. Innovations are emerging, like biodegradable packaging and reusable containers. These changes reflect a newfound commitment to protecting our planet.

The trend towards automation is also noteworthy. Smart packaging systems can optimize supply chains. They reduce excess materials and enhance efficiency. However, implementing these technologies can be challenging. Companies must balance costs with the benefits of modernization. Not all businesses are prepared for such transitions.

Consumer preferences are shifting as well. More people favor brands that prioritize sustainability. This influences manufacturers to rethink their packaging strategies. They face the pressure to adapt quickly. Yet, not every company can keep pace with these shifts. Engaging with sustainable practices requires reflection and dedication. It's a complex journey, and many are still finding their way.

Future Trends in Industrial Packaging for Sustainable Manufacturing

Related Posts

-

Exploring the Future of Industrial Packaging: Trends and Innovations Driving Sustainability

-

Understanding the Future of Industrial Packaging Innovations and Sustainability Trends

-

The Future of Packaging Machines Innovations Transforming the Industry

-

How to Choose the Right Industrial Packaging Equipment for Your Business Needs

-

Top 10 Industrial Packaging Machines Transforming Efficiency with 2023 Data

-

Top Material Handling Supplies for Improved Warehouse Efficiency