NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Top 10 Industrial Packaging Machines Transforming Efficiency with 2023 Data

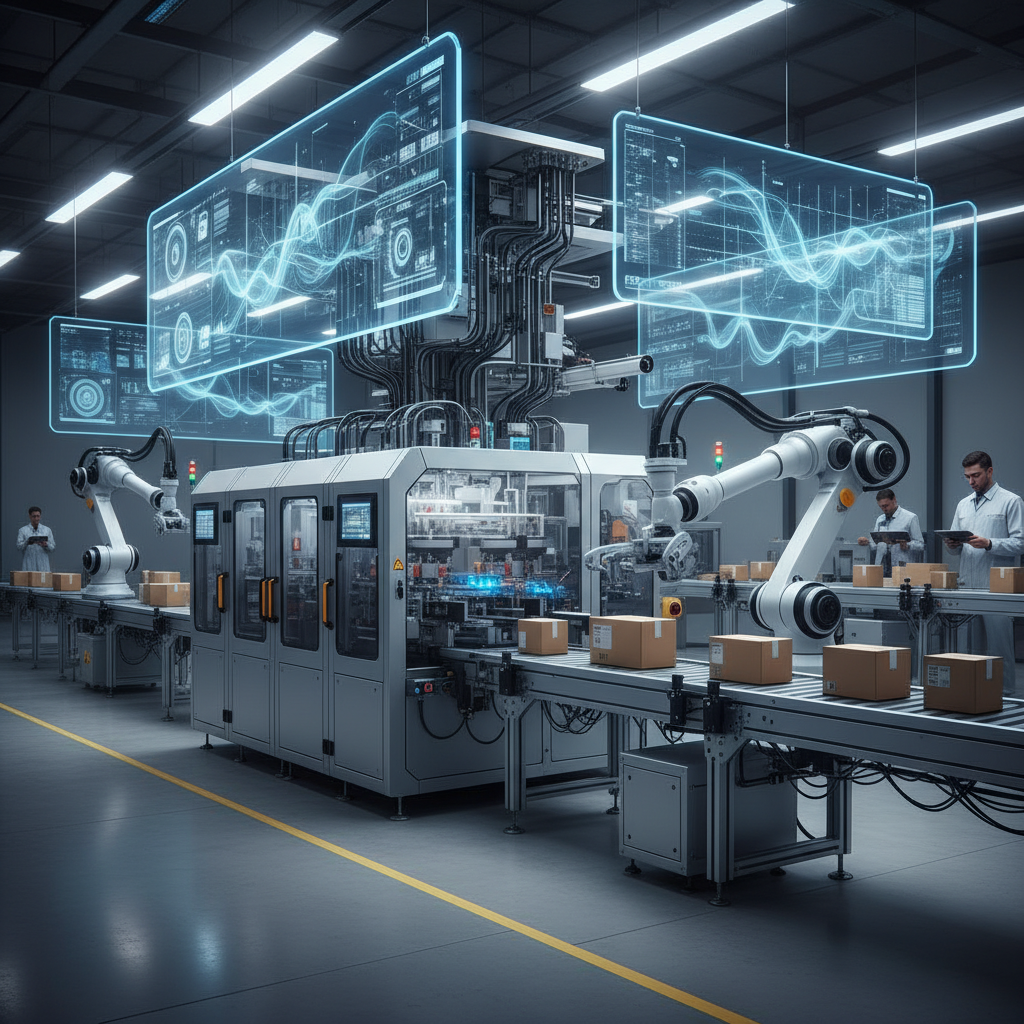

In an era where efficiency and innovation drive industrial success, the role of industrial packaging machines has never been more critical. As businesses strive to streamline their operations while maintaining high standards of product safety and quality, these machines are evolving rapidly to meet the demands of diverse industries. John Smith, a leading expert in the realm of industrial packaging, emphasized the importance of this evolution when he stated, “The future of industrial packaging machines lies in their ability to adapt and enhance operational efficiency through technology.”

With the advent of advanced technology and data analytics, the packaging machinery sector is experiencing a transformative phase in 2023. From automation to smart packaging solutions, the latest innovations are setting new standards in performance and sustainability. As manufacturers continue to seek ways to reduce costs and improve throughput, understanding the top industrial packaging machines that are setting trends becomes essential for anyone keen on maintaining a competitive edge. This article delves into the top 10 industrial packaging machines making waves in efficiency, leveraging 2023 data to highlight how they are reshaping the landscape of industrial operations.

Top 10 Industrial Packaging Machines Enhancing Operational Efficiency

In 2023, the landscape of industrial packaging continues to evolve, driven by advancements in technology that enhance operational efficiency. According to a report by MarketsandMarkets, the global industrial packaging market is projected to reach $64.38 billion by 2027, growing at a CAGR of 4.7%. This growth is largely attributed to innovative packaging machines that optimize production lines, reduce waste, and ensure product safety during transportation.

Key among these developments are automated packaging solutions that utilize AI and robotics. A survey conducted by the Packaging Machinery Manufacturers Institute indicates that 62% of companies have adopted automation to improve their packaging processes. Automated systems not only speed up production rates but also significantly lower labor costs and minimize human error. For instance, companies integrating robotic arms into their packaging lines reported a 30% increase in throughput, demonstrating how modern machinery can transform operational efficiency in industrial settings.

Furthermore, the implementation of data analytics in packaging machines is reshaping how manufacturers monitor and enhance their processes. With IoT-enabled devices, real-time data collection allows businesses to track system performance and identify bottlenecks promptly. According to a study by Gartner, companies leveraging data analytics in their packaging operations experienced a 20% improvement in output efficiency, underlining the importance of technology in today’s competitive market. As 2023 progresses, these advancements will continue to play a pivotal role in driving efficiency and sustainability in industrial packaging.

Key Features and Innovations of 2023's Leading Packaging Machines

The rise of innovative packaging technologies in 2023 is reshaping the efficiency of industrial packaging processes. Key features of the leading packaging machines include enhanced automation, smart sensors, and integrated systems that streamline operations. These advancements not only elevate productivity but also contribute to significant reductions in operational costs. Additionally, the integration of artificial intelligence and the Internet of Things enables real-time monitoring and data analysis, which further optimizes packaging workflows.

Sustainability also plays a pivotal role in the evolution of packaging machinery. Many of the top machines now incorporate environmentally friendly materials and processes, reflecting the growing demand for sustainable solutions in the packaging industry. Innovations such as active packaging and nanotechnology not only help extend product shelf life but also minimize waste, aligning with the increasing emphasis on eco-conscious business models. As the global packaging market continues to expand, these key features and innovations will be critical in driving efficiency and sustainability in 2023 and beyond.

Impact of Automated Packaging Solutions on Production Costs in 2023

The industrial packaging sector is experiencing significant transformation through automated solutions that dramatically enhance production efficiency. According to recent market analyses, the food automation market is projected to grow from $6.04 billion in 2023 to $14.4 billion by 2032, representing a compound annual growth rate (CAGR) of 10.15% during the forecast period. This growth is driven by increasing demands for packaging efficiency across various sectors, including food, pharmaceuticals, and consumer goods.

Moreover, the sustainable packaging equipment market is expected to exceed $157.6 billion by 2024, spurred by a surge in e-commerce and an emphasis on environmentally friendly packaging solutions. Analysts predict that from 2025 to 2034, this market will witness a CAGR of over 7.3%. The expansion of automated packaging technologies not only reduces production costs but also enhances the speed and reliability of the packaging processes, showcasing the undeniable impact of automation on the industry's operational dynamics.

Impact of Automated Packaging Solutions on Production Costs in 2023

Sustainability Trends in Industrial Packaging Machines for Eco-friendly Practices

The industrial packaging sector is witnessing a significant shift towards sustainability, with key innovations aimed at reducing environmental impacts. In 2023, companies are increasingly adopting eco-friendly practices that prioritize the use of recyclable and biodegradable materials. As consumers demand greener options, manufacturers are responding by integrating sustainable materials into their packaging solutions, which not only meet regulatory standards but also enhance brand loyalty among environmentally conscious customers.

Technological advancements are also playing a critical role in promoting sustainability within industrial packaging machines. Automation and machine efficiency have improved dramatically, enabling companies to minimize waste during the packaging process. For example, smart packaging machines now utilize real-time data to optimize material usage, ensuring that minimal resources are expended while maximizing product protection. These innovations are crucial in addressing the rising concerns of plastic pollution, allowing industries to transition towards more sustainable packaging solutions that benefit both the environment and the bottom line.

Top 10 Industrial Packaging Machines Transforming Efficiency with 2023 Data - Sustainability Trends in Industrial Packaging Machines for Eco-friendly Practices

| Machine Type | Efficiency Rating (%) | Sustainability Score (1-10) | Energy Consumption (kWh/ton) | Recyclable Materials (%) |

|---|---|---|---|---|

| Automatic Carton Erector | 92 | 8 | 150 | 95 |

| Heat Seal Packaging Machine | 89 | 7 | 120 | 90 |

| Fill-Seal Machine | 95 | 9 | 100 | 85 |

| Vertical Form Fill Seal Machine | 91 | 8 | 110 | 88 |

| Case Packer | 90 | 8 | 140 | 92 |

| Labeling Machine | 94 | 9 | 130 | 86 |

| Pallet Wrapper | 87 | 7 | 115 | 89 |

| Shrink Wrap Machine | 88 | 6 | 125 | 84 |

| Bagging Machine | 93 | 8 | 105 | 91 |

| Vacuum Packaging Machine | 96 | 10 | 95 | 93 |

Market Growth Statistics for Industrial Packaging Machinery in 2023

The industrial packaging machinery sector is witnessing significant growth in 2023, driven by the increasing demand for efficiency and automation across various industries. The global case packing machines market is projected to expand from USD 1.07 billion in 2024 to USD 1.74 billion by 2033, indicating a robust compound annual growth rate (CAGR) as industries seek advanced solutions to enhance production capabilities and reduce labor costs. Additionally, the Packaging Automation Market is poised to rise to USD 52.2 billion, highlighting a trend toward automation that aligns with the evolving needs of manufacturers.

Moreover, the pharmaceutical packaging equipment market is expected to experience substantial growth, anticipated to reach USD 12.6 billion by 2034 from USD 6.1 billion in 2024, with a CAGR of 7.5%. As companies continue to embrace technology advancements, the modular packaging equipment market is also forecasted to increase significantly, climbing from USD 15.83 billion in 2025 to around USD 25.00 billion by 2034. These statistics underscore the critical role that innovative packaging machinery plays in improving operational efficiency and meeting market demands in 2023 and beyond.

Related Posts

-

Why Industrial Packaging Machines Are Essential for Modern Manufacturing Success

-

10 Essential Tips for Choosing the Right Packaging Machines: Maximize Efficiency and Reduce Waste

-

Maximizing Efficiency: The Future of Bagging Equipment in the Food and Beverage Industry

-

The Future of Filling Machines in Sustainable Packaging Innovations

-

Top 5 Automated Filling Machines for Efficient Production in 2023

-

How to Choose the Right Industrial Packaging Equipment for Your Business Needs