NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Top Material Handling Supplies for Improved Warehouse Efficiency

Efficient warehouse operations are critical to the success of any supply chain, and one of the key elements that contribute to this efficiency is the use of appropriate material handling supplies. These supplies encompass a wide assortment of tools and equipment designed to optimize the movement, storage, and control of goods within a warehouse environment. With the demands of modern logistics increasing, finding the right material handling supplies can make a significant difference in reducing labor costs, minimizing errors, and enhancing overall productivity.

In today's competitive market, warehouses must adapt quickly to changing requirements and technologies. Investing in top-quality material handling supplies not only ensures that your workforce operates with maximum efficiency but also helps to maintain an organized and safe workspace. From pallet jacks and forklifts to shelving systems and conveyor belts, the right equipment can streamline processes and improve the flow of products, ultimately translating to better service and satisfaction for your customers. Emphasizing the most effective materials and tools is essential for any operation striving for excellence in warehouse management.

Overview of Material Handling Supplies in Warehousing

Material handling supplies play a crucial role in enhancing the efficiency of warehouse operations. These supplies encompass a diverse range of equipment and tools designed to facilitate the movement, storage, control, and protection of materials within a warehouse. Essential items include pallet jacks, forklifts, shelves, bins, and conveyor belts, each contributing to a streamlined workflow. By utilizing these supplies effectively, warehouses can minimize labor costs and reduce the risk of workplace injuries, ultimately fostering a safer and more productive environment.

In addition to traditional equipment, innovative material handling supplies are increasingly making their way into warehouses. Automated systems and advanced inventory management tools have revolutionized how materials are handled, leading to improved accuracy and speed. Technologies such as RFID tags and barcode scanners enable real-time tracking of inventory, allowing for better stock management and reduced retrieval times. These advancements not only optimize space utilization but also enhance overall operational efficiency, setting the foundation for a modern, Agile warehouse environment.

Top Material Handling Supplies for Improved Warehouse Efficiency

| Item | Description | Applications | Benefits |

|---|---|---|---|

| Pallet Jacks | Manual or powered equipment to lift and move pallets. | Loading/unloading trucks, moving products within a warehouse. | Increases mobility and reduces manual strain. |

| Forklifts | Powered industrial trucks for lifting heavy loads. | Storage, loading, and transportation of heavy goods. | Efficiently handles heavier items with minimal effort. |

| Conveyor Belts | Mechanized systems for transporting materials within a facility. | Assembly lines, sorting centers, and packaging. | Enhances speed and efficiency, reducing manual handling. |

| Storage Racks | Shelving systems designed for organizing goods. | Optimizing space for inventory management. | Maximizes storage space and improves access to products. |

| Hand Trucks | Two-wheeled devices used for transporting smaller items. | Deliveries, stocking shelves, moving boxes. | Reduces physical strain and enhances maneuverability. |

| Strapping Machines | Equipment for securing packages with straps. | Packaging, shipping, and bulk storage. | Improves load stability and prevents damage during transport. |

Types of Material Handling Equipment and Their Functions

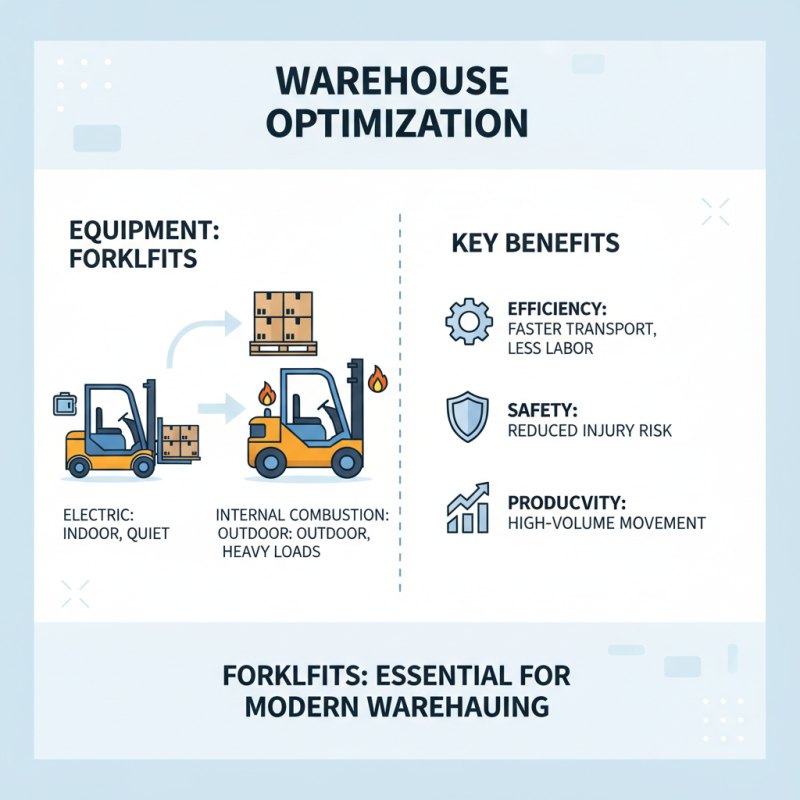

Material handling equipment plays a crucial role in optimizing warehouse operations by improving efficiency and safety. One of the most common types is the forklift, a versatile vehicle designed to lift and transport heavy loads over short distances. Forklifts come in various designs, including electric and internal combustion models, each suited for different environments and load capacities. They are essential for moving pallets, materials, and even bulky items, significantly reducing manual labor and the risk of injury.

Another vital category includes conveyors, which are used to transport goods and materials across various warehouse locations. Conveyors can be configured in a multitude of ways, including belt, roller, and overhead systems, each designed to streamline processes based on the nature of the items being moved. These systems enhance productivity by minimizing the need for manual pushing or carrying, facilitating smooth flow and organization of inventory.

Additionally, storage systems such as shelving and pallet racks are fundamental in optimizing space efficiency within a warehouse. These systems not only assist in organizing products but also improve accessibility, ensuring that items can be retrieved quickly and safely. With the proper material handling equipment, warehouses can maximize their operational efficiency and adapt to changing inventory demands with ease.

Key Features to Consider When Selecting Supplies

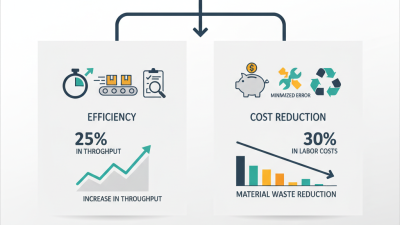

When selecting material handling supplies to enhance warehouse efficiency, it is crucial to consider several key features that can directly impact operations. According to a recent report by the Material Handling Industry of America (MHIA), improving operational efficiency in warehouses can lead to a productivity increase of up to 25%. This improvement often stems from the careful selection of equipment that not only supports workload ergonomics but also facilitates faster movement of goods.

Ergonomics play a vital role in reducing physical strain on employees. Equipment such as adjustable height workstations and ergonomic hand tools can decrease the incidence of workplace injuries by up to 50%, as highlighted in a study by the Occupational Safety and Health Administration (OSHA). Additionally, choosing supplies that enhance visibility and organized storage, like clearly labeled bins or modular shelving systems, can minimize time spent searching for items, thereby increasing throughput. The effective integration of RFID technology has also shown promise, with a report from the Aberdeen Group indicating that companies using RFID for inventory management can reduce out-of-stock situations by 30% and improve inventory accuracy by 99%.

Lastly, flexibility and scalability of material handling supplies should also be a priority. As the demand for faster fulfillment grows—eCommerce has seen a 25% annual growth rate over the past five years—supplies that can adapt to changing needs are essential. Modular systems that can be easily reconfigured or expanded help businesses respond swiftly to evolving market conditions and improve overall inventory flow. Investing in supplies that embody these features not only optimizes warehouse operations but also positions businesses for long-term success.

Benefits of Efficient Material Handling Solutions

Efficient material handling solutions are critical for enhancing warehouse productivity. By streamlining the movement of goods, businesses can significantly reduce the time it takes to process orders. Implementing advanced handling technologies, such as automated guided vehicles and conveyor systems, not only minimizes manual labor but also decreases the risk of human error. This ensures that products are moved swiftly and accurately, enhancing overall workflow and reducing bottlenecks that can hinder operations.

Furthermore, efficient material handling contributes to better space utilization. With the right systems in place, warehouses can be designed to maximize vertical space and optimize layout configurations. This leads to less congestion in aisles and a more organized environment, which can improve safety and decrease the likelihood of accidents. In turn, a safer workplace fosters employee morale and productivity, which are essential for long-term operational success. Investing in efficient material handling solutions ultimately translates into cost savings and a competitive edge in the market.

Strategies for Implementing Effective Material Handling Systems

Implementing effective material handling systems is crucial for enhancing warehouse efficiency. One key strategy is to conduct a thorough analysis of the current workflow and identify bottlenecks that impede productivity. By observing how materials are moved and stored, businesses can pinpoint areas for improvement. This could involve rearranging the layout for better accessibility or eliminating unnecessary steps in the handling process, thus ensuring that materials are transported swiftly and safely.

Another vital approach is to invest in training staff on the best practices for material handling. Educating employees on equipment use, safety protocols, and efficient techniques can significantly reduce errors and accidents in the warehouse. Additionally, encouraging a culture of continuous improvement allows staff to contribute ideas for optimizing processes. Coupling this training with the right material handling supplies—such as ergonomic tools, appropriate shelving, and advanced automation solutions—can amplify the positive effects on overall efficiency and productivity within the warehouse setting.

Top Material Handling Supplies for Improved Warehouse Efficiency

Related Posts

-

How to Choose the Best Packaging Supplies for Your Business in 2025

-

Top 2025 Automated Bagging Systems: Benefits, Trends, and Innovations

-

Maximizing Efficiency: The Future of Bagging Equipment in the Food and Beverage Industry

-

How to Choose the Right Filling Machines for Your Packaging Needs

-

Benefits of Automated Packaging for Efficiency and Cost Reduction

-

Top 10 Trends Shaping the Future of the Packaging Industry in 2023